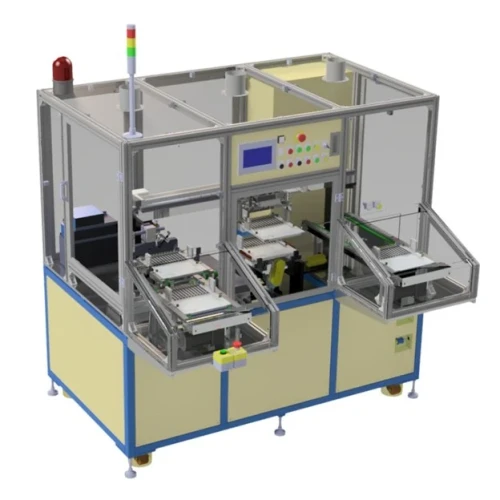

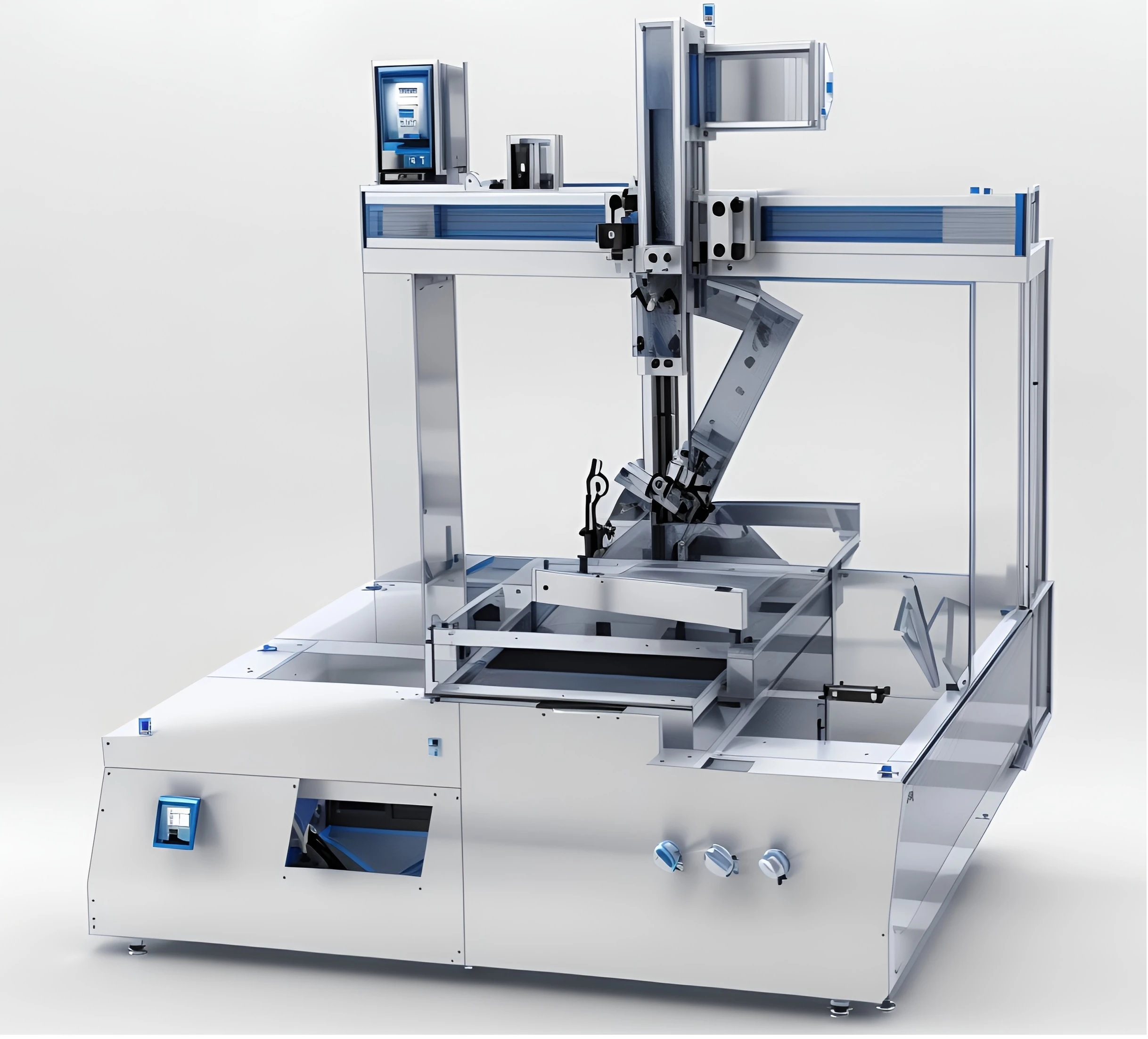

The vertical-type PCB flux spraying machine is a specialized device used in the electronics manufacturing process to apply a thin and uniform layer of flux onto printed circuit boards (PCBs). Flux is a natural resin extracted from pine trees and is commonly used as a fluxing agent in electronic assembly to facilitate the soldering process, protect the circuit board from oxidation and dust, and improve heat dissipation.

Vertical PCB flux spraying machine

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Hotline: +84.916 63 9355 / +84.915 74 4664

Email: Sales01@cncvina.com.vn / Sales03@cncvina.com.vn

Product description

Introduction to vertical PCB flux spraying machine

The vertical PCB flux spraying machine is a specialized automatic device used to coat flux onto the surface of printed circuit boards (PCBs). It is widely applied in the electrical, electronics, telecommunications, electronic components, and computer industries. Flux is a natural resin extracted from pine trees and is commonly used as a fluxing agent in electronic assembly to promote soldering by removing oxidation from metal surfaces.

Outstanding features of the vertical PCB flux spraying machine

The vertical PCB flux spraying machine offers the following standout features:

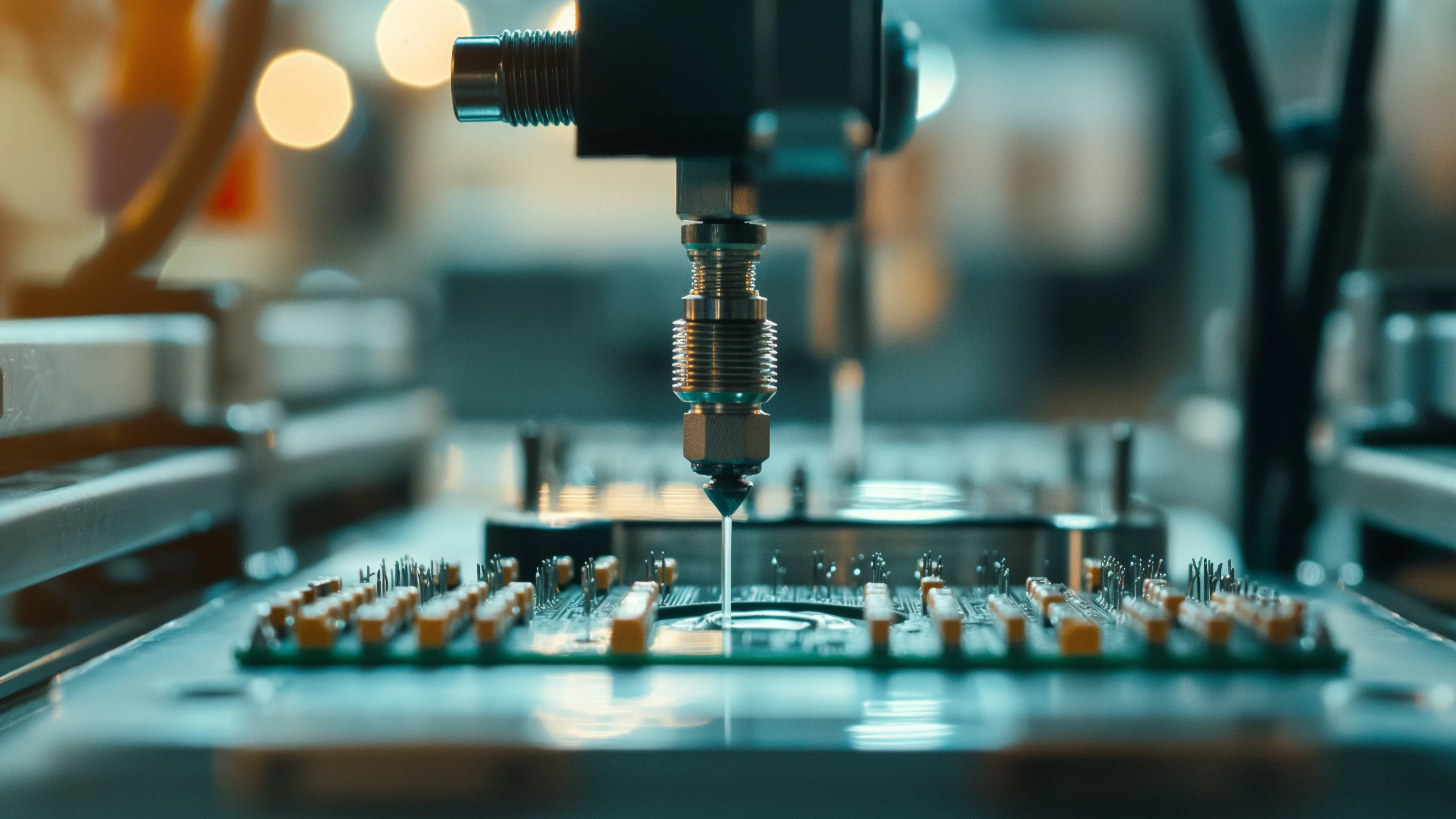

1. Adjustable spray nozzle

The adjustable spray nozzle allows precise control over spray patterns and coverage areas, ensuring even application of flux on the PCB.

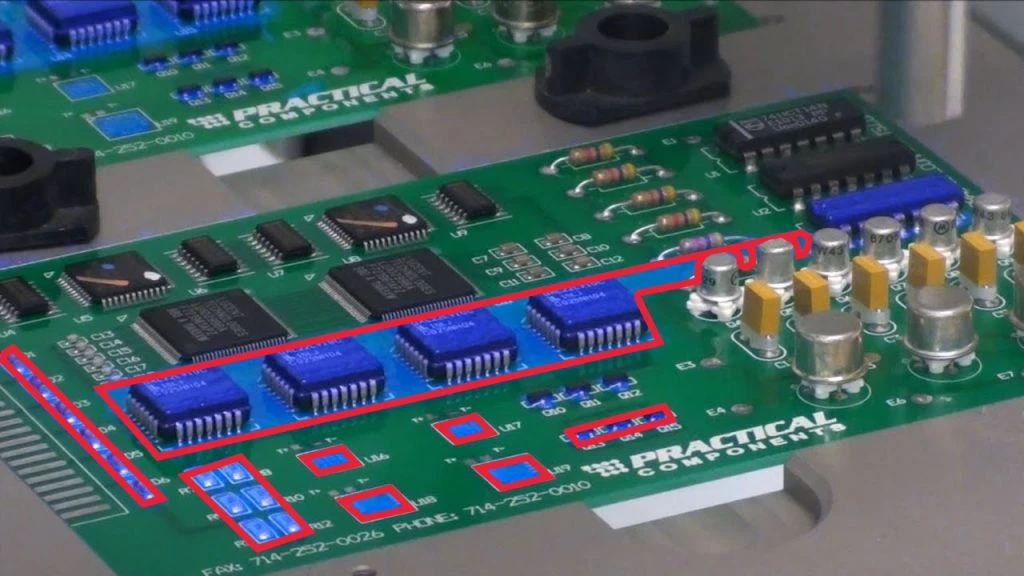

2. Programmable parameters

The ability to store and recall specific spray parameters such as spray pressure, nozzle position, and spray duration helps achieve consistent and repeatable results.

3. Automatic cleaning function

The auto-cleaning feature supports machine maintenance, prevents clogging, ensures smooth operation, and extends the lifespan of the sprayer.

4. User-friendly interface

A user-friendly interface with intuitive controls and settings makes it easy for operators to set up and efficiently operate the vertical flux spraying machine.

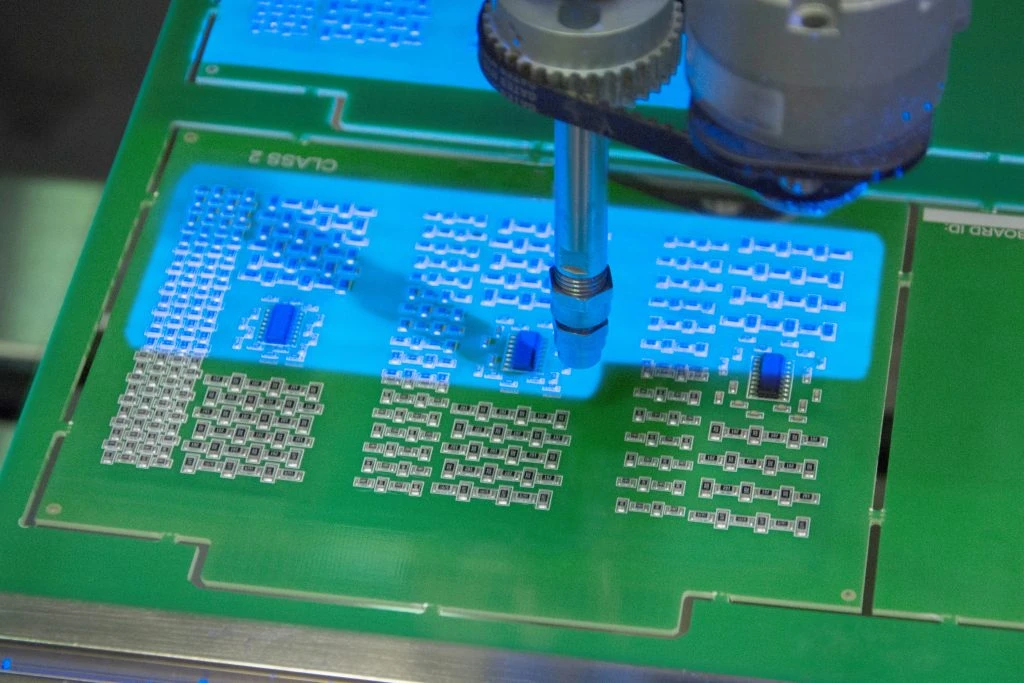

5. High precision and accuracy

The vertical flux spraying machine delivers high precision and accuracy, ensuring a uniform coating on PCBs while minimizing the risk of defects or inconsistencies.

6. Safety features

A vacuum system collects mist and excess fluid around the spraying area to avoid contamination on the PCB surface. Additional features such as overload protection, emergency stop button, and safety interlock systems help ensure operator safety and prevent accidents.

7. Cost efficiency

-

The machine saves up to 80% of adhesive compared to conventional spraying systems and supports scalability with various models.

Technical specifications of the vertical PCB flux spraying machine

| Dimensions | L2200 x W1500 x H2100 mm |

| Power supply | 1 phase/220V - 50Hz |

| Air supply requirement | 0.4-0.6 MPa |

| Conveyor speed | 220 mm/s |

| Flux spray head speed | 250 mm/s |

| Jig transfer unit speed | 250 mm/s |

| Tank volume | 10-liter adhesive tank, 1-liter cleaning tank |

| PCB height | 910±20 mm |

| Conveyor width | 50~450 mm (adjustable) |

Common methods for applying flux coating on PCBs

There are various methods to apply a flux coating to electronic circuit boards. The appropriate method depends on production volume and specific requirements, typically determined by the following factors:

Manual spraying

Used in low-volume production or when equipment is unavailable. Flux can be applied using spray bottles or handheld spray guns. This method is time-consuming and may require masking. Moreover, the quality and consistency depend heavily on the operator’s skill, often resulting in variations from board to board.

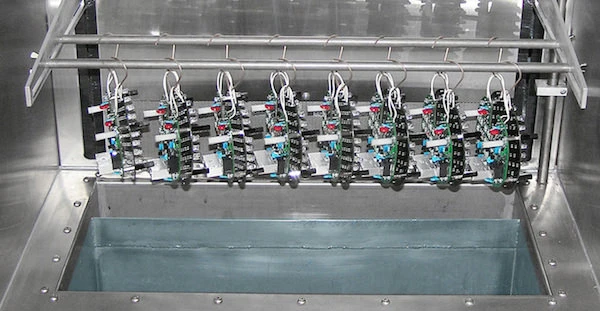

Dipping

A common coating method for mass production assemblies. Dipping is only suitable when both sides of the PCB are to be coated. The immersion speed, withdrawal speed, dwell time, and flux viscosity determine the resulting film quality.

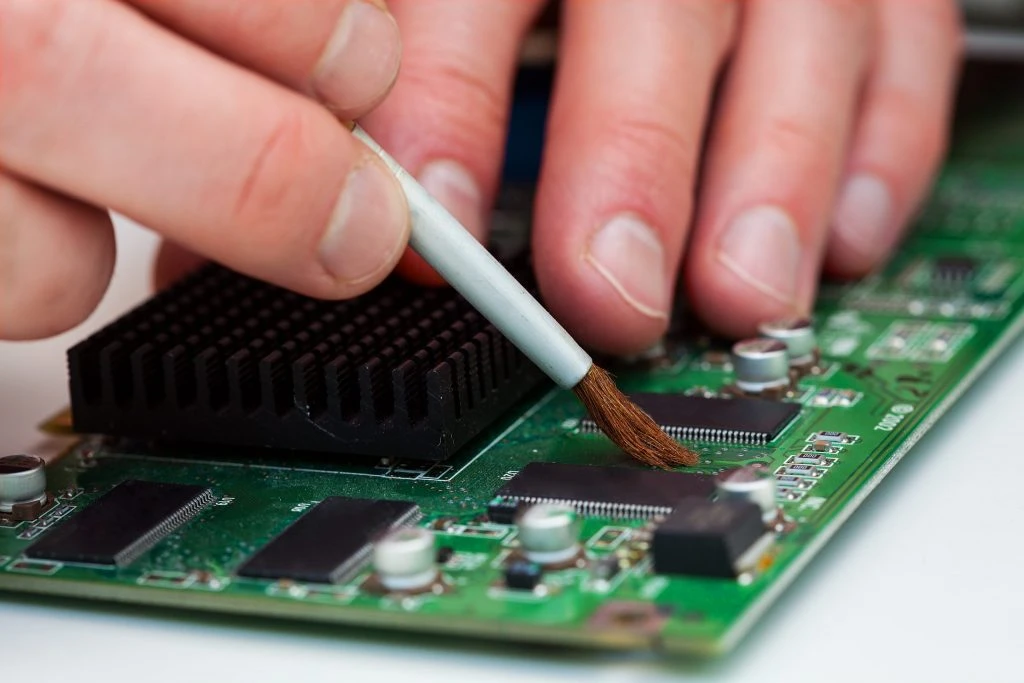

Brushing

This method is primarily used for touch-ups and rework. The coating is applied to specific areas on the PCB rather than the entire board. While cost-effective, brushing is labor-intensive and inconsistent, making it more suitable for small-scale operations.

Advantages and disadvantages of flux coating for PCBs

Advantages

Among various protective solutions for electronic circuit boards such as potting or encapsulation, conformal coating offers a distinctive advantage: it protects with just a thin layer of material. This thinness yields multiple benefits during PCB operation, including resistance to chemicals, dust, moisture, and improved heat dissipation.

-

The minimal thickness adds negligible weight and volume to the PCB, which is crucial in compact, high-precision designs.

-

The thin film enables faster heat transfer, reducing the risk of component damage or corrosion due to high temperatures.

-

Compared to potting or encapsulation, conformal coating allows easier inspection and repair of the PCB.

-

The coating exerts minimal mechanical stress on electronic components, particularly beneficial for components with thin or fragile leads.

Disadvantages

Despite its benefits, conformal coating also has certain drawbacks that must be carefully considered for a reliable coating process:

-

It is rarely suitable for environments with high exposure to moisture or water. Though it can protect against humidity, the coating is usually semi-permeable and not waterproof.

-

It contains volatile organic compounds (VOCs) in the solvent.

-

It is not effective in protecting PCBs from vibration or physical impact due to its thinness.

Why choose CNC VINA for designing and manufacturing vertical PCB flux spraying machines?

The PCB flux spraying machine for the electronics industry is one of many types of specialized automated support equipment that CNC VINA has supplied to Japanese and Korean clients for over 16 years. With extensive experience in automation, CNC VINA is confident in delivering the best solutions, fastest turnaround, and most reasonable costs to our customers. Additionally, with a reliable warranty policy and a dedicated maintenance team, we are always ready to support you 24/7.

For inquiries about automated machinery, please contact:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Phone: +84.916 63 9355 / +84.915 74 4664

Website: https://cncvina.com.vn; https://cncvina.net; https://cncviname.com.vn

Email: sales01@cncvina.com.vn

Tiếng

Anh

Tiếng

Anh

Tiếng Anh

Tiếng Anh