Conveyor belt - CNC VINA is one of the leading companies in conveyor belts, conveyor systems in automatic machines, and industrial systems. With experience in designing, manufacturing and installing automation equipment and customized conveyors according to customer requirements. We can help you provide a complete, turnkey service from start to finish. In addition, free enthusiastic consultation and professional maintenance services bring satisfaction to customers.

BELT CONVEYOR

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Hotline: +84.916 63 9355 / +84.915 74 4664

Email: Sales01@cncvina.com.vn / Sales03@cncvina.com.vn

Product description

Belt conveyor - Conveyor system is a device, a handling system in manufacturing plants, factories and logistic warehouses used to transport materials and goods from location A to location B according to calculations. before.

Those positions can be the starting and ending points of the conveyor belt, or they can also be points in the conveyor belt's journey corresponding to the production stages.

Products transported on conveyor belts usually have a fixed and similar journey. However, in current sorting lines, goods moving on a conveyor system with sorting equipment and technology will have different destinations depending on the purpose of the person.

Types of conveyor belts

Flat belt conveyor

Flat belt conveyors are one of the most popular conveyor systems in use today. Flat belts are useful for the internal transportation of items within a factory.

This type of conveyor uses a series of powered pulleys to move a continuous flat belt, which may consist of natural materials or synthetic fabrics that are placed on top of a moving conveyor belt and carried from one end to the other. .

Since its belts can be made of different materials, this type of conveyor is extremely versatile. Flat belt conveyors are divided into integrated motor type, head drive type and middle drive type.

Flat belt conveyor

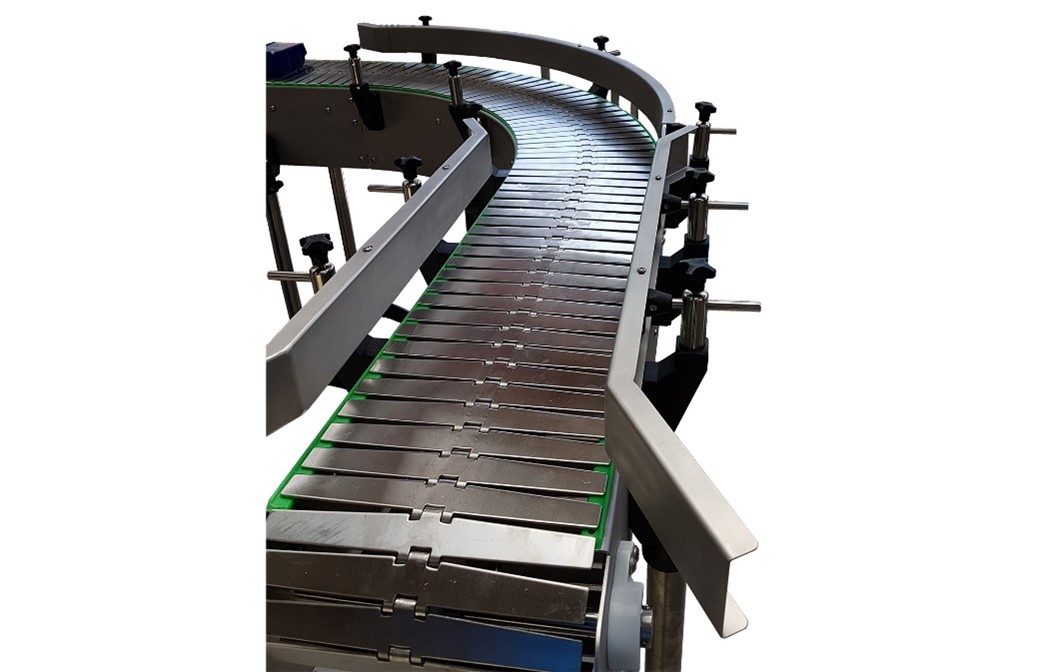

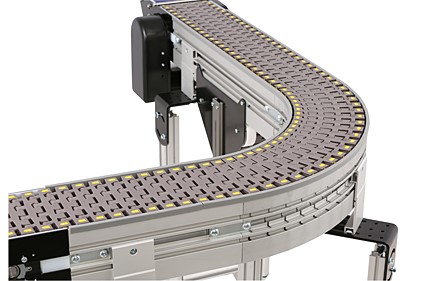

Modular belt conveyors

Modular conveyors use a single ring made up of a multitude of interlocking pieces, usually made of rigid plastic. These segments can be removed and replaced individually, as opposed to having to remove the entire belt. This makes modular conveyors simpler to maintain and repair than their flat conveyor counterparts.

Modular conveyors are well suited to applications that involve moving around corners. In fact, it is possible to go straight, around a corner, incline and down using a single belt.

Modular belt conveyor

Slotted belt conveyor

Slotted belt conveyors have barriers in their design with spacers that can hold loose materials in place during inclines and slopes, to create some distance between items.

-

“T” Form: Type of shim that stands perpendicular to the belt surface, providing support and flexibility for handling delicate items. It is suitable for light duty tasks, such as transporting small parts, packaged items, and food products.

-

“L” Form: The wide base of the cleat makes it more resistant to lever forces. This type of barrier is designed to carry light to medium weight bulk materials up steeper inclines.

-

“V” Form: Pads of this shape are typically 2 inches or less in height to create a sliding effect, often for transporting abrasive, heavy or large bulk materials.

Slotted belt conveyor

Inclined belt conveyor

The inclined conveyor has a central drive, gear motor and loading with a single or double tip. Instead of using a conveyor belt with a smooth surface, this type of conveyor belt has a rough surface on the conveyor belt, usually to transport products up or down, but there is a certain limit with an upward tilt of no more than 18°.

Inclined belt conveyor

Trough conveyor

The trough conveyor has a large loading and transportation capacity, using multi-layer rubber belts. Trough belts typically operate on a flat, horizontal or inclined surface, but only up to 25 degrees. The belt must have a large enough radius so that it can still contact all the rollers in the chute.

Trough idler rollers have a central roller with a horizontal axis of rotation, two outer rollers (wing rollers) with one axis raised at an angle to the horizontal.

Trough conveyors are widely used in mining, cement, and animal feed processing. Trough conveyor belts can transport bulk materials with large densities such as coal, ore, soil, grain, etc.

Trough belt conveyor

Mobile conveyor

With wheels installed at the bottom of the mobile conveyor, it can move freely according to human purposes and is mainly used in environments with small transportation tilt angles.

Mobile conveyors are mainly used in places where loading and unloading locations are frequently changed such as ports, wharves, railway stations, coal plants, warehouses, construction sites, sand and stone factories, farms... to transport and Loading and unloading within short distances.

Mobile belt conveyor

Retractable belt conveyor

The frame of the retractable conveyor is equipped with a belt storage device, which can make the belt stretch freely in the length direction and adjust the conveyor length according to the change of the belt's working position at any time. any.

Retractable conveyors are the most efficient machines and are often used in the continuous transportation of materials. It is the main equipment of coal conveying system in coal refinery and power plant.

Steel belt conveyor

Steel belt conveyors use stainless steel belts instead of conventional rubber and plastic belts. Rubber or plastic conveyor belts will release toxic substances when transporting high-temperature materials, but steel conveyor belts will not, making them suitable for many automated production applications such as robots and processing. food, solar panel production...

Special belt conveyor

Special conveyors are designed specifically to transport goods in special cases, with a small range of applications. Some of these are:

-

Fiberglass conveyor belt: made of fiberglass. They are useful for tasks that require extreme temperatures.

-

Metal conveyors: equipped with metal nodules for better handling of complex machines and their parts.

-

Narrow width conveyors: are the best choice for handling small items.

-

Backlit conveyors: They come with lights fixed on the conveyor belt to aid in quality control.

-

Vacuum conveyor: it creates suction to keep light products on the line despite slopes and high speeds.

-

Magnetic conveyor belt: can transport iron-containing materials through evenly spaced electromagnets placed inside the conveyor belt.

Technical characteristics of belt conveyor.

Conveyor specifications often depend on the customer's application, industry, and product type. Therefore, CNC VINA will advise on the design and selection of customized conveyor types, this is to ensure that the conveyor system is manufactured to suit that application.

There are things to consider such as conveyor belts for the food industry that must be suitable for washing and sterilization.

Belt conveyors can create static electricity as they move around the pulleys. When transporting components that are sensitive to static electricity, this can be harmful to the product so it will be manufactured with anti-static technology.

Some items may be sensitive to vibration or pressure or may be hazardous materials. Therefore, these should be researched to find solutions to deal with the risks ensuring the belt conveyor is designed to be fit for purpose.

Application of belt conveyor

Thus, due to the benefits of belt conveyors such as saving labor time, being very flexible and being able to transport many different types of goods. Using belt conveyors also saves space, as fewer people are used to move items. Therefore, transporting products between stations in the production and processing chain becomes simple and efficient.

Some applications of belt conveyors are:

-

In mining: To move coal, ore or salt.

-

In the airport: Transporting luggage.

-

On the farm: move crops, grains, and fruits when harvesting.

-

In the warehouse: Transporting goods to and from the delivery area.

-

In production: Transporting products, goods, and components.

Conveyor belt structure.

Conveyor frame system

The system's frame holds all moving parts together for safe and secure operation. The conveyor belt is composed of a structural frame made of box steel, shaped steel, and stainless steel with support legs that can be aligned and fixed to the factory floor or hung on other structures.

Conveyor belts

This product is suitable for conveying materials that are separate, resistant to a lot of abrasion, and have large shock forces, especially suitable for highly stable and inclined working environments.

Belt support

These are rollers that support the conveyor belt in the right direction and quickly maintain motion. The rollers keep objects in place and prevent the belt from sagging.

Conveyor belt movement

A motor that can use a variable or constant speed reduction gear to provide kinetic energy for the conveyor belt. The engine is connected to a rotating shaft called the active drum through a gearbox, belt, etc. At the end of the conveyor belt there is another rotating roller called the passive drum.

Pulley drives conveyor belt

The conveyor belt must loop over two or more strategically positioned pulleys. Pulleys control belt motion and perform important functions such as driving, redirecting, rotating, tensioning, and tracking the belt.

Some notes on belt conveyor selection

Belt conveyor material

Conveyor belt materials commonly used by most industries are PVC and polyurethane (PU). Some industries require thicker belts to make the belt more durable. In addition, the choice of conveyor belt thickness is also considered based on the application and conveyor design. Attention should be paid to conveyor belt materials to prevent static electricity and conduct electricity.

Betl conveyor surface

The surface of the conveyor belt can be smooth, rough or greasy. Its surface characteristics can affect the performance of the conveyor belt.

Shipping products

The most important factor to consider before choosing a conveyor is the product you want to transport. This is mainly because the material and surface of the conveyor belt is chosen based on the products that will be transported.

Special belt conveyor

There are some conditions that require special types of belts during the transportation of materials or products, so special conveyors are needed such as:

Food and beverage industry conveyors are required to meet Good Manufacturing Practice (GMP) standards set by the Indonesian Ministry of Industry, requiring the use of food grade conveyors such as PU conveyors or tissue conveyors. heat.

Why should you choose CNC VINA to design and manufacture conveyor belts?

With experience in designing, manufacturing and installing automation equipment and customized conveyors according to customer requirements. We can help you provide a complete, turnkey service.

In addition, free enthusiastic consultation and professional maintenance services bring satisfaction to customers.

Customers with needs for industrial conveyors and automation solutions for smart factories please contact:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Factory: Song Cung Industrial Site, Dong Thap Commune, Dan Phuong District, City. Hanoi Vietnam

Phone: +84.916 63 9355 / +84.915 74 4664

Website: www.cncvina.com.vn; www.cncvina.net

Email: sales01@cncvina.com.vn / sales03@cncvina.com.vn.

Tiếng

Anh

Tiếng

Anh

Tiếng Anh

Tiếng Anh