Jig for hanging paint products

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Hotline: +84.916 63 9355 / +84.915 74 4664

Email: Sales01@cncvina.com.vn / Sales03@cncvina.com.vn

Product description

Overview of jigs (Jig) for hanging paint products

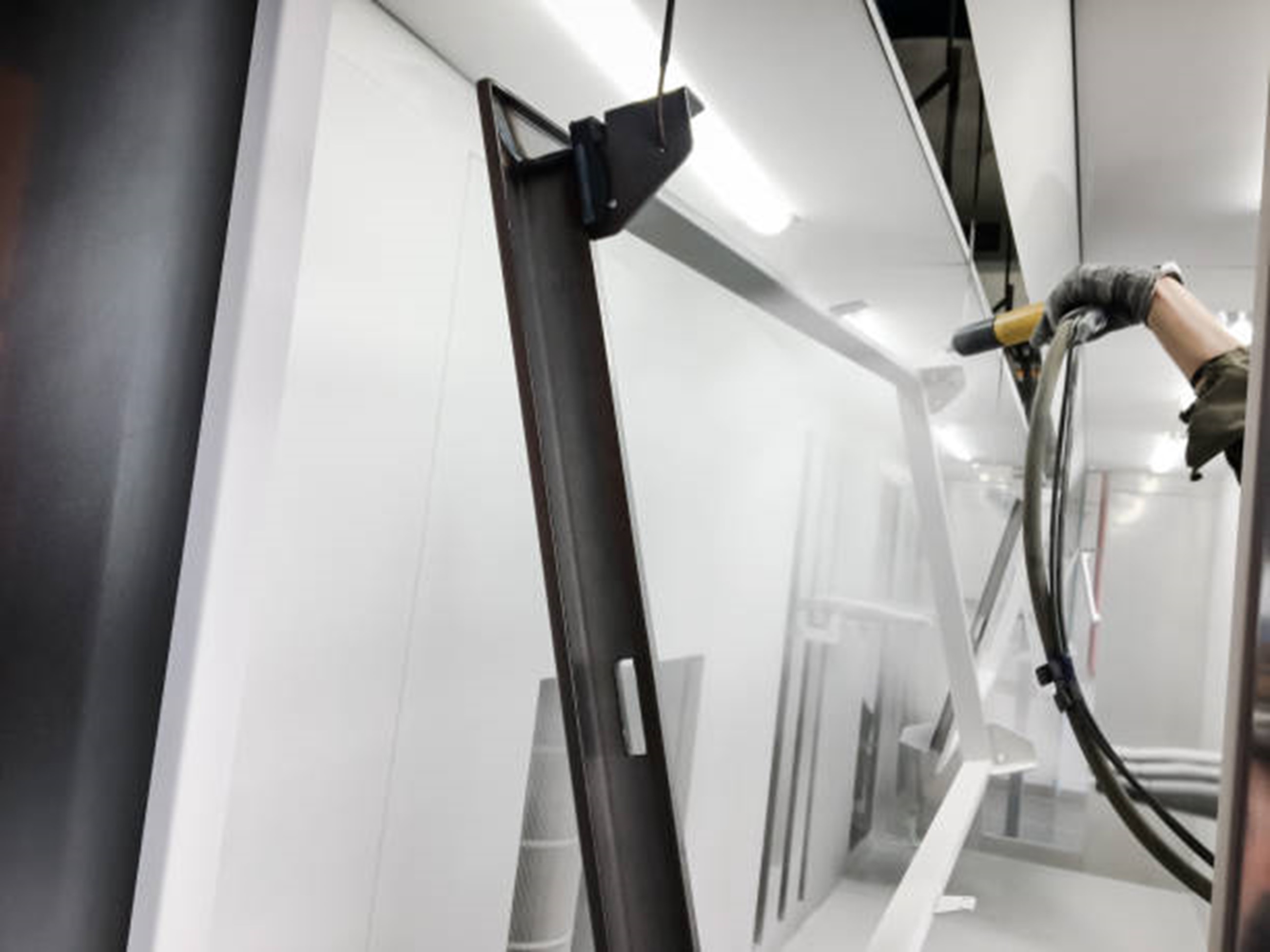

Jig hanging paint products in the paint line: Optimal solution for the paint industry

In the process of manufacturing cars, motorbikes and household appliances, painting is an indispensable step to create products with high gloss, durability and aesthetics. However, to achieve the best painting efficiency, the paint jig system plays an extremely important role.

VINA CNC Company is one of the leading units in the field of providing mounting solutions, Jig systems and product hanging fixtures in automatic painting lines. With our experience and professionalism, we are committed to providing customers with high quality products, ensuring strict technical requirements and the most optimal design.

Requirements for jigs (Jig) to hang painted products on the automatic plastic painting line

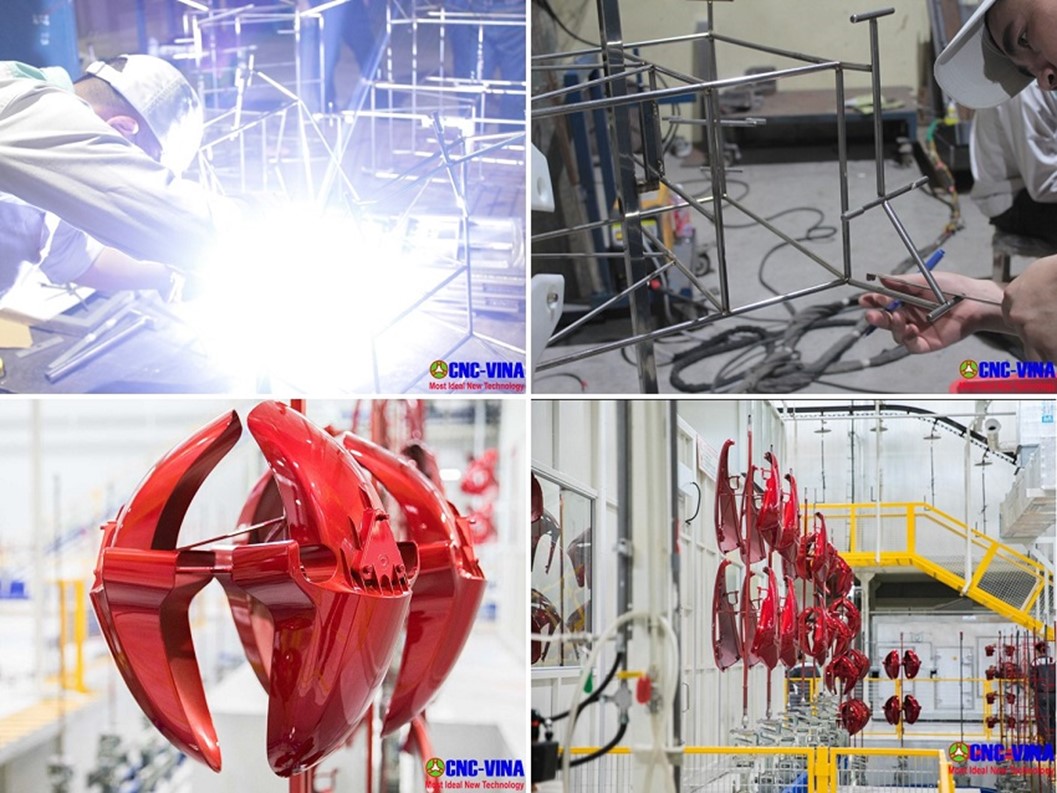

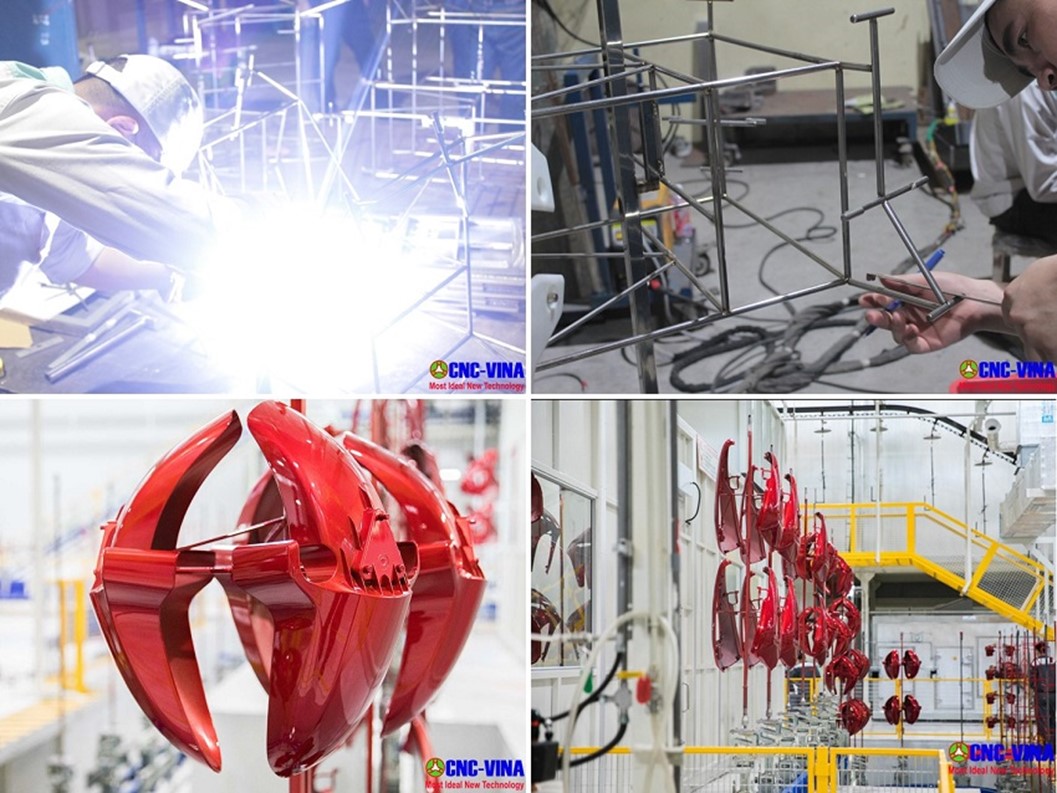

The process of manufacturing, designing and measuring paint hanging jigs is carried out in great detail.

Jig hangs paint products used in automatic robotic painting lines, so it requires very high precision.

Always ensure strict requirements during the painting process such as:

· Do not deform when burned at 6000C.

· The part connected to the conveyor is machined to an accuracy of ± 0.5mm.

· The distance between two opposite parts is 400mm and the same face is 200m.

· There is a tester included to check.

· Spray water pressure P = 1.0 – 1.2 kg/cm2.

· Details do not have water stagnation on the surface.

· The part does not fall off the Jig when running at a speed of 1.8m/min with air pressure P = 6 kg/cm2.

Types of jigs (Jig) for hanging paint products

Hanging jig

Description and function

Paint product hangers are designed in many shapes, they can be straight bars, horizontal bars, truss systems, cables, etc. with mechanisms and hooks used to clamp the product tightly during the spraying process. paint. They can be designed to be fixed to the factory floor, mobile on wheels or fixed to the wall or ceiling.

Benefits and disadvantages

Hanging jigs have the advantage of being quite simple in structure so the cost is not high. They can be combined together to install multiple products at the same time, saving time and paint. They can also be combined to form jig conveyor systems.

However, a disadvantage of the hanging fixture is that the product is fixed throughout the painting process. When you want to paint multiple sides of the product, you must move the nozzle or reposition the product.

This wastes time and is suitable for products that only need to be painted on one side or for manual production lines. One solution is to arrange many nozzles in many directions, but this will increase equipment costs.

Rotating jig

Description and function

Basically, rotating jigs for paint products are similar to hanging jigs. They are also designed in many shapes, fixed or movable, etc. The main difference is that these types of jigs are equipped with additional rotating shafts, usually driven by motors or compressed air.

Benefits and disadvantages

The rotating jig basically solves the disadvantages of the hanging jig, it helps to coat many surfaces of the product without having to reset the jig or arrange or move too many nozzles, it helps save time. and increase the flexibility of the coating process.

However, due to the additional degrees of freedom, the structure becomes more complex and comes with a price tag. There are additional issues that need to be calculated such as rotation direction, rotation angle, rotation speed and other factors such as control, stuck errors, risk of entanglement in moving mechanisms, etc.

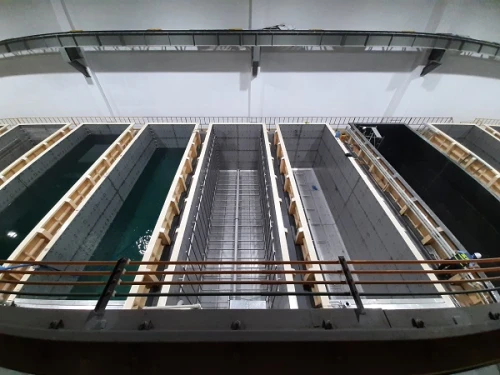

Jig conveyor

Description and function

The jig conveyor is a conveyor system designed with a special surface with mechanisms to attach a series of paint product jigs that can be hanging or rotating. They are often found in highly automated coating lines.

They come in two common forms: the bottom moving conveyor attached to the floor, the attachments facing up or the hanging conveyor moving overhead with the attachments facing down.

Benefits and advantages

The jig conveyor can hold a series of products at once. Its cyclic movement combined with automatic paint booths helps to maximize the time spent on coating operations as well as promote automation and reduce receiving costs. process and increase the quality of product surface coating.

What needs to be considered is that the cost of investing in such a fixture conveyor system is very large because of the complexity in design, number of details, fixtures, control systems, etc., not every business can afford it. can invest.

Advantages of jigs (Jig) for hanging paint products in the paint line

Consistency

With a paint jig, the product is held in a fixed position, ensuring the paint is applied consistently throughout. This eliminates the risk of uneven coating, providing a professional and consistent finish.

Save time

By hanging the product on the Jig, the painting process by robot or automatic nozzle takes place faster and more effectively. This helps increase production productivity and reduce customer waiting time.

Achieve high painting efficiency

Thanks to hanging the product on the Jig, the painting process is done accurately and evenly over the entire product surface. This helps achieve high painting efficiency, creating products with high gloss, durability and aesthetics.

Cost-effective

Using a painting jig can save on labor costs because fewer workers are needed to hold and position the product during the painting process. Additionally, a consistent and efficient painting process can reduce material waste, saving money in the long run.

Easy to assemble and disassemble the product

With a smart design, the painted product hanging Jig makes mounting and dismantling the product after painting easy and quick. This saves staff time and effort, while minimizing the risk of product damage.

Disadvantages of jigs (Jig) for hanging paint products in the paint line

Requires high initial investment costs

Installing a Jig system to hang paint products in the paint line requires quite a large initial investment cost. However, with the efficiency and time savings of Jig painting, capital will quickly be recovered.

High technical requirements

Designing and installing a Jig system for hanging paint products requires high expertise and technique. This can make it difficult for small businesses to apply this technology to the production process. However, CNC VINA will design and provide the optimal and fastest solution to meet product quality requirements during the painting process.

Things to consider when performing installation

Requires space

Space available for jig (Jig)

Fixtures for paint products are usually not too large, however when the jigs place the products on the space they occupy can be very large. Choosing an area with a large enough space is very important to carry out the painting process conveniently, easily and effectively.

Plan the optimal layout

Planning the optimal layout of the workshop not only helps save space but also helps the process of operating and transporting workpieces in and out more quickly and effectively. In addition, paint is a toxic material, optimally arranging the coating area helps ensure labor safety to avoid affecting people working around or in other areas.

Integrate with existing equipment

Ability to integrate with existing painting lines

Product painting lines can have many different levels of automation, accompanied by differences in equipment, the process of performing operations, etc. If the design of the jig can be integrated with existing equipment, with little or no impact on the line having to change its structure, it will bring great savings in costs for upgrading and renovating.

Consider upgrading and adding equipment

Consider upgrading and renovating to expand production and increase productivity. Will the current or soon-to-be-used jig system be able to meet that requirement?

Designing jigs that can accommodate changes in the production process will bring great economic benefits.

Safety measures

Safety measures for personnel

Some common labor protection equipment used in paint factories include gloves, protective clothing to help prevent paint splashes from sticking to the body, oxygen and anti-splash masks, protective shoes, etc.

Warning systems, signs, sirens, symbols, characters, etc. are essential to help warn workers about dangerous risks in the workshop

Compliance with standards

There are many standards related to workshops or coating lines such as standards for electrical equipment, electrical safety, ventilation standards, labor protection standards, etc. Some standards are industry-specific, some are general standards. These standards may be regulated by each country differently. Some standards are in the law that need to be followed.

In general, following the set standards will help make the production process safer and more efficient because they are not created to make things difficult for businesses, they are experiences to ensure a certain level of safety for businesses. people and production process, they are also valuable documents for designing and arranging an efficient, high-productivity workshop.

Customers who need JIG to hang paint products, please contact:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY Factory: Song Cung Industrial Site, Dong Thap Commune, Dan Phuong District, City. Hanoi Vietnam

Phone:+84.915 74 4664 / +84.915 74 0880 Fax: +84.24.37805007

Website: www.cncvina.com.vn ; www.cncvina.net

Email: Sales01@cncvina.com.vn / Sales03@cncvina.com.vn

Tiếng

Anh

Tiếng

Anh

Tiếng Anh

Tiếng Anh