Application of vehicle identification number engraving machines in the automative industry

Introduction

Description

The automatic numbering machine utilizes advanced engraving and inspection technologies with capabilities such as barcode recognition, camera checking, and error control, significantly minimizing mistakes and code mismatches. The machine is designed to engrave product numbers, text labels, identification codes, and serial numbers onto metal surfaces with fast speed, high precision, sharp and aesthetic engravings.

This machine is suitable for various materials including iron, steel, aluminum, copper, stainless steel, and plastic. It can mark on both flat and cylindrical surfaces. Customers can choose between pneumatic or electronic operation depending on their specific application needs.

Structure of the automatic numbering machine

-

Robust and optimized machine frame.

-

Worktable moves the product into position for engraving and ejects it afterward; the fixture is easily adjustable to accommodate different models.

-

Specialized engraving head using router bits or laser marking.

-

Integrated camera system for inspecting engraved characters and numbers.

Benefits of the automatic vehicle frame number engraving machine

-

Globalization & record keeping: In a rapidly globalizing world, standardized numbering systems for products and documents are crucial, fueling demand for automatic numbering machines.

-

Digital transformation: As companies transition to digital records and documents, there's an increasing need for automatic numbering systems that seamlessly integrate with digital workflows.

-

Efficiency & error reduction: Automatic numbering machines speed up the process and minimize human error, making them valuable tools in quality control.

-

Regulatory compliance: Many industries like healthcare and finance require accurate numbering for compliance and auditing.

-

Customization & flexibility: Modern machines offer high levels of customization and adaptability to meet diverse business requirements.

Innovations in automatic numbering machines

-

Digital integration: Many machines now feature software interfaces to integrate with digital record systems, reducing the need for manual data entry.

-

Smart numbering: Some machines include AI control systems that generate numbers based on predefined criteria, ensuring consistency and accuracy.

-

Mobile accessibility: Mobile apps and remote control options allow users to operate the machines via smartphones or tablets, enhancing convenience.

-

Efficiency features: Innovations in cartridges, marking speed, and usability make these machines faster and more user-friendly.

-

Multifunctionality: Some machines now combine numbering with other functions like time-stamping, increasing their utility.

Common automotive applications

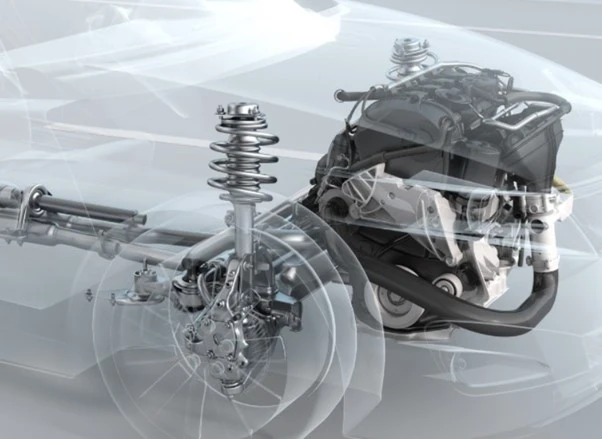

Engine engraving

Engraving on engine parts ensures traceability of components sourced from various suppliers. Once marked, each engine can be identified, stored, and tracked throughout its production and operational lifecycle. You can engrave 2D codes, DataMatrix™ codes, serial numbers, shift codes, assembly plant codes, production dates, VINs, logos, and more.

Direct 2D marking on automotive parts eliminates production errors. It enables quality control at every production stage and allows all product data to be stored in a centralized database via the engraved codes.

Exhaust & emission filter marking

Serial numbers and DataMatrix codes are engraved using the same machine. The engraved image meets OEM specifications, complies with production cycle time, and maintains a low-noise environment—creating a quiet, non-disruptive workplace. This allows you to trace, monitor, inspect, and archive part/component data by engraving information like logos, part numbers, DataMatrix codes, shift codes, production codes, and dates.

Fiber laser marking

An excellent solution for marking components of the exhaust system, such as mufflers and emission filters, due to high contrast engraving results. It allows you to mark brand labels and traceability information quickly and efficiently within short cycle times. The marking process is noiseless, even when working on hollow parts.

It meets safety standards with a compact, powerful engraving system that communicates easily with main servers, PCs, PLCs, scanners, and barcode systems. The permanent engraving ensures lifelong traceability.

Chassis & frame engraving

- Ensures that information engraved on vehicle frames and chassis remains permanent.

- Deep and clear marking guarantees that identification stays intact, durable, and unalterable over time.

Scribing engravers / Dot peen markers

Capable of deep and fast engraving, both before and after surface treatment. No noise is generated during the marking process. Suitable for large parts.

Plastic part marking

With fast marking speed and high contrast, it is ideal for internal traceability and production line automation, ensuring visual quality. The machine can replace costly alternatives like inkjet printing and label sticking.

Technical specifications of CNC VINA's numbering machine

| Max marking area | 120x40 mm |

| Engraving head stroke | 100 mm |

| Height from floor to jig surface | 900 mm |

| Distance from table edge to jig position | 305 mm |

| Cycle time | 35-40s, không tính thời gian gá lắp |

| Marking method | Vạch dấu |

| Power supply | 220V |

| Power consumption | 3kW |

| Air pressure | 0.5-0.6 Mpa |

| Machine weight | 800 kg |

Conclusion

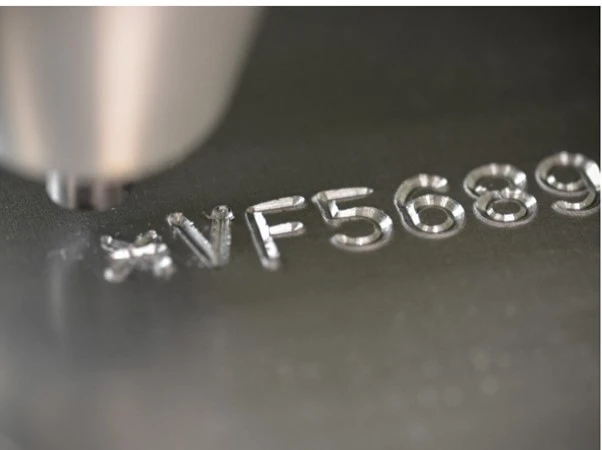

Numbering machine applications are diverse. In the automotive sector, VIN engraving plays a vital role in vehicle identification, quality management, and fraud prevention. The Vehicle Identification Number (VIN) is a 17-character unique identifier that provides information about the manufacturer and technical specifications of the vehicle.

VIN engraving helps track vehicle origin and history, supports legal and insurance processes, and prevents VIN tampering or forgery, reducing theft risks. Repair and maintenance workshops use VINs for information lookup, optimizing workflow. Moreover, VINs assist manufacturers in inventory management, efficient production, regulatory compliance, data analysis, and new product development. If you have any questions regarding automotive frame number marking machines, feel free to contact CNC VINA for prompt assistance!

Tiếng

Anh

Tiếng

Anh

Tiếng Anh

Tiếng Anh