What is an Engine Number Engraving Machine: Benefits and Applications

Introduction

Definition of Engine Number Marking Machine

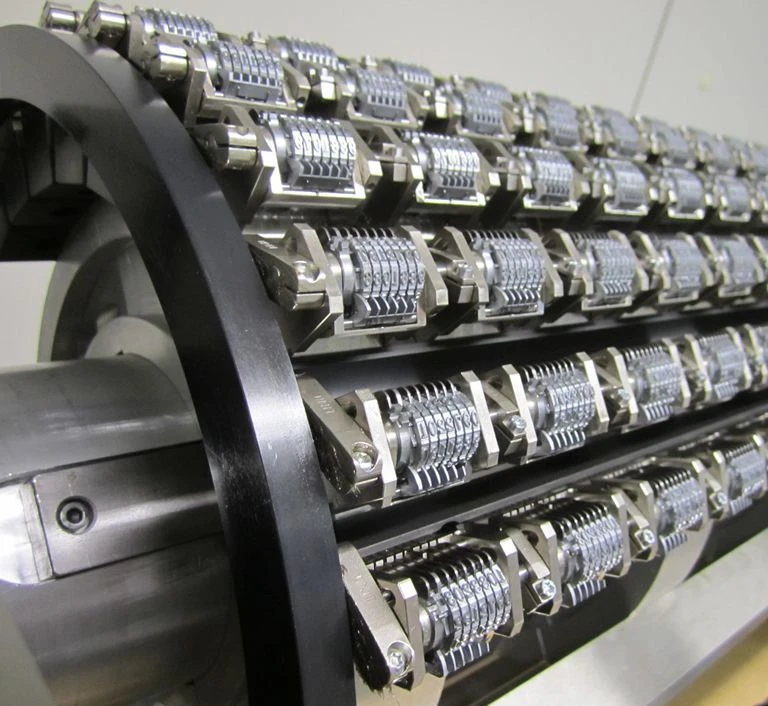

An engine number marking machine is an automation device designed to label and number engine components or related parts. By utilizing laser engraving, ink printing, or other marking technologies, this machine creates unique identifiers for each product, facilitating tracking and quality control throughout the manufacturing and management process.

Importance of Engine Number Marking Machines in Various Industries

In today’s manufacturing environment, maintaining product quality and managing product information are crucial. Engine number marking machines play a key role in ensuring the accuracy of product information and efficient data management. They help enhance product quality, improve security, ensure regulatory compliance, and provide reliability and transparency for both businesses and customers.

Benefits of engine number marking machines

Improved traceability and quality control

-

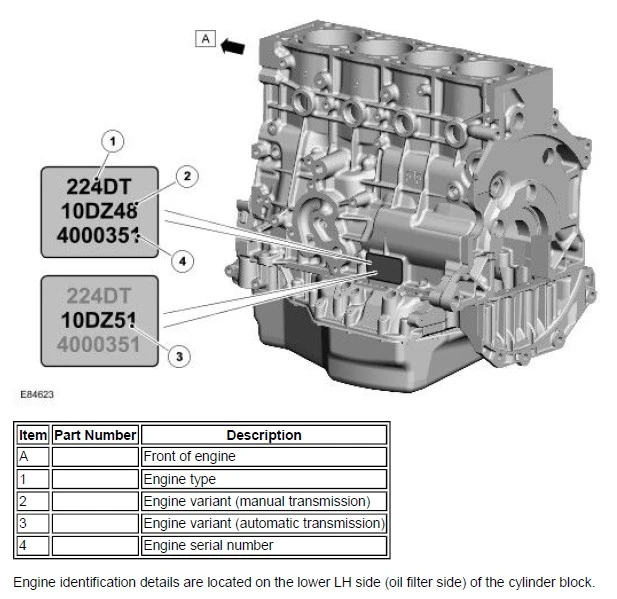

Ability to track and identify individual engine components: Engine number marking machines allow direct marking of identification information on each engine component from production to usage. This facilitates easy identification of the origin and quality of each part, enhancing comprehensive quality control.

-

Ensuring proper assembly and minimizing errors: The information marked on each engine component ensures correct assembly and adherence to manufacturing procedures, reducing errors and enhancing product consistency.

Compliance with Regulations and Standards

-

Meeting legal requirements for identification and documentation: Engine number marking machines assist businesses in complying with legal requirements related to product identification and information management.

-

Achieving certifications and maintaining compliance: By providing accurate and transparent data, engine number marking machines help businesses obtain certifications and maintain compliance with industry standards and regulations.

Applications of engine number marking machines

Automotive Industry

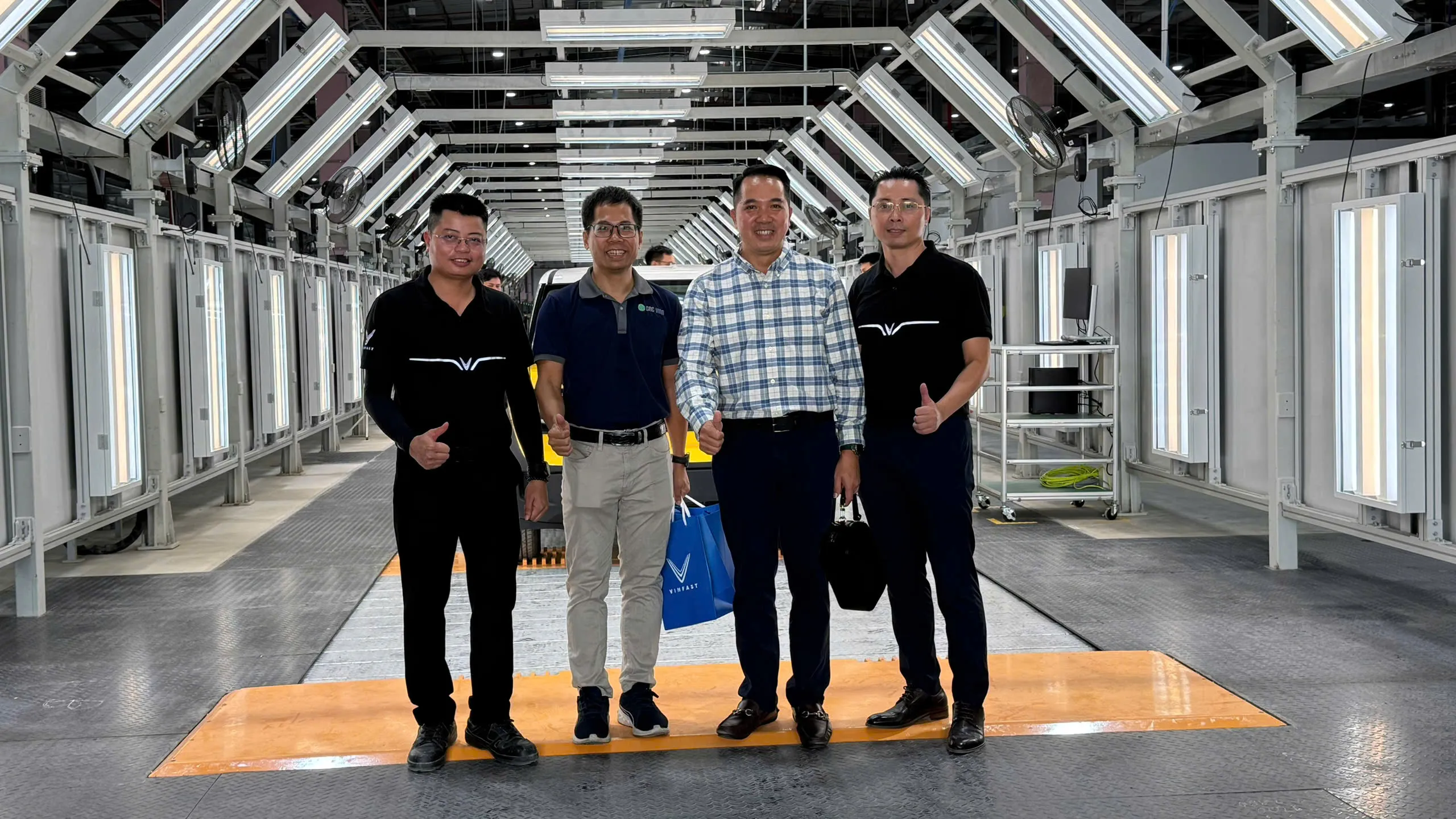

In the automotive industry, engine number marking machines play a crucial role in managing and tracking engines used in vehicle manufacturing.

-

Engine identification for vehicle manufacturers: Each engine is assigned a unique identification, including technical specifications and production history. This helps manufacturers determine the origin and quality of each engine, ensuring consistency and performance in the final product.

-

Tracking engine components for maintenance and recalls: The information linked to each engine component facilitates monitoring their operational status. This is critical for carrying out scheduled maintenance and product recalls in case of defects.

Aerospace industry

In the aerospace sector, engine reliability and safety are paramount.

-

Engine identification for aircraft manufacturers: Engine number marking machines support the identification and recording of information for engines used in aircraft production. This helps in quality control and ensures flight safety.

-

Traceability for maintenance and safety purposes: Detailed information on the origin and history of each engine aids in proper maintenance and ensures operational safety.

Industrial equipment sector

In this field, engine number marking machines play a significant role in equipment management and maintenance.

-

Engine numbering for heavy machinery manufacturers: Directly marking identification information on each engine helps in efficiently and safely managing heavy industrial equipment.

-

Monitoring and tracking for maintenance and inventory purposes: Detailed data on engine operation facilitates effective maintenance planning and equipment inventory management.

Medical equipment industry

In the healthcare sector, reliability and safety of medical equipment are crucial.

-

Engine identification for medical equipment manufacturers: Engine number marking machines help identify and manage engine information used in medical devices such as medical imaging machines and radiotherapy systems.

-

Ensuring patient safety and regulatory compliance: Detailed engine information ensures patient safety and adherence to industry regulations and standards.

CNC VINA engine ưnumber marking machine specifications

| Machine dimensions | 900 (W) x 1500 (D) x 1800(H) |

| Operating height | 850 mm from the floor |

| Main power supply | AC 1 phase 220V, 50Hz |

| Control power supply | DC 24V |

| Power consumption | 1KW |

| Weight | 550 kg |

Conclusion

Engine number marking machines not only improve product quality and security but also enhance efficiency and regulatory compliance. Their applications span from the automotive industry to the medical field, aiding in production enhancement and information management.

Engine number marking machines play an irreplaceable role in ensuring product quality and information management in today’s manufacturing environment.

With their numerous benefits and potential, the adoption of engine number marking machines is highly encouraged, helping businesses optimize production processes and manage information more effectively.

Tiếng

Anh

Tiếng

Anh

Tiếng Anh

Tiếng Anh