CNC VINA's Sharing at VINFAST on Localization of Automotive and Motorcycle Parts Manufacturing

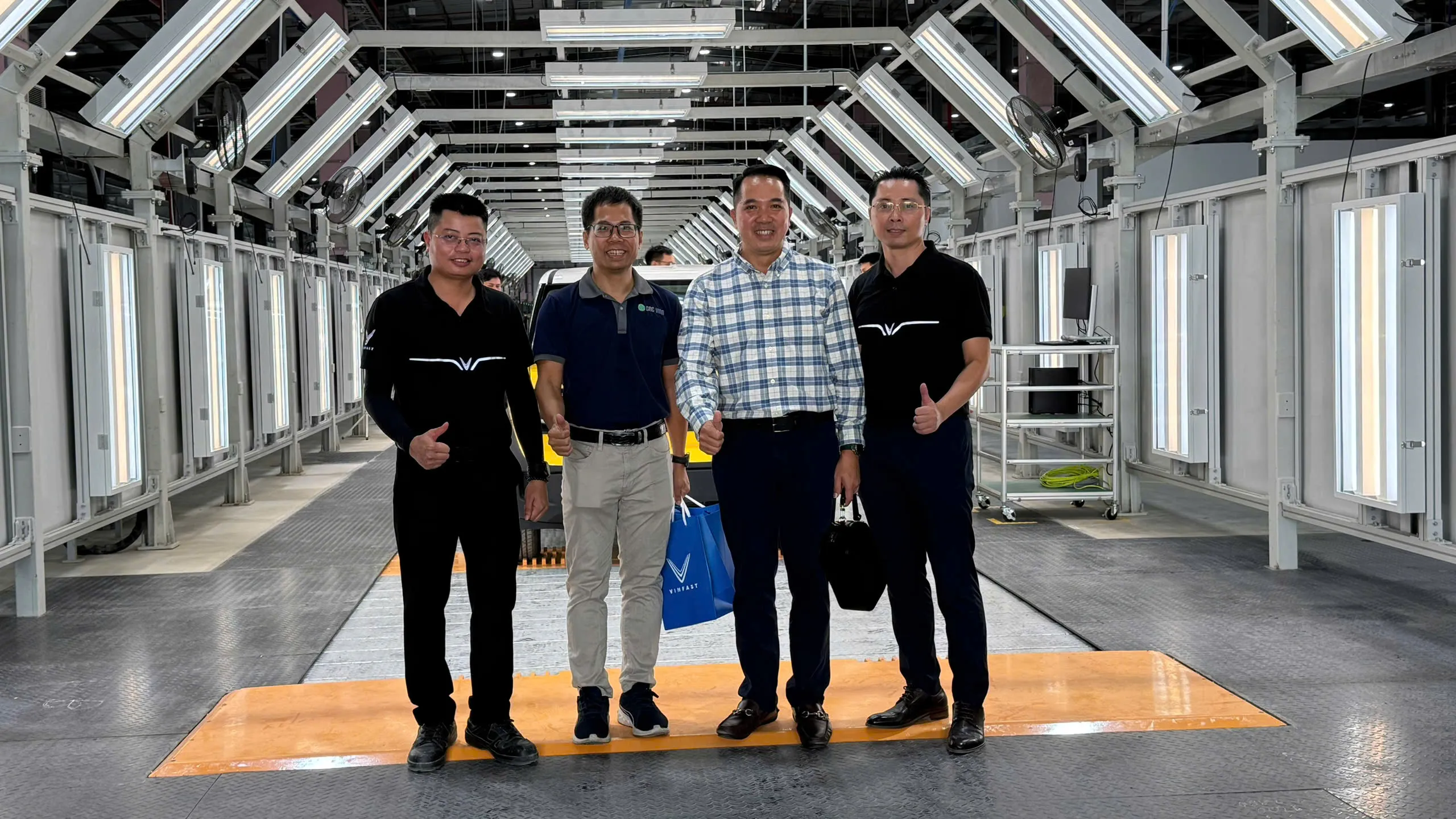

At the Seminar on VinFast Automobile Localization

-large.webp)

On December 12, a seminar on VinFast automobile localization was held at the VinFast factory in Hai Phong. The event attracted the participation of leading industry experts and auxiliary suppliers. CNC VINA was honored and proud to be one of the suppliers attending the seminar.

The Vietnamese automaker aims to achieve an 84% localization rate for its pure electric vehicles by 2026, compared to the current rate of over 60%.

At the VinFast automobile manufacturing plant in Hai Phong on December 12, 2024, Mr. Dao Anh Van, CEO of CNC VINA, shared

"In 2017, when VinFast started construction of its automobile and motorcycle manufacturing plant in Dinh Vu Industrial Park, CNC VINA was among the first contractors, partnering with international firms to supply and install metal painting, plastic painting, and electric motorcycle assembly lines. These lines have been operating effectively, contributing to VinFast's stable and high-quality production."

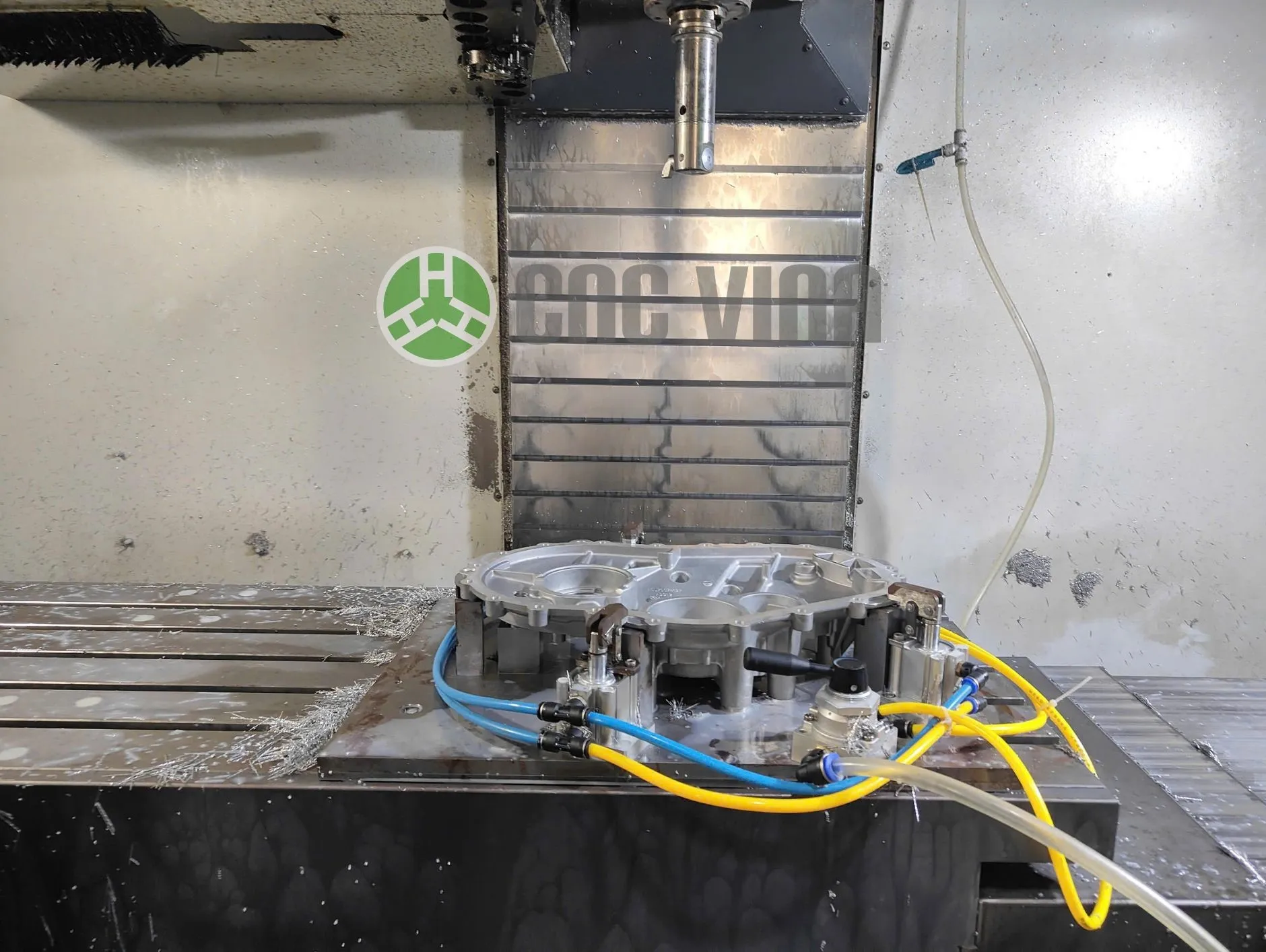

"By 2020, CNC VINA started supplying prototype machining parts for the chassis of VinFast's electric vehicles during the trial production phase."

"In 2021, CNC VINA continued its investment by acquiring 250 CNC machines, including five 5-axis machining centers and large-scale machining equipment over 4 meters in size from Japan and Germany. This investment enabled CNC VINA to become a key supplier of machined components such as battery trays and motor housings for VinFast. With these achievements, I am confident that Vietnamese enterprises, including CNC VINA, can fully participate in the domestic and export-oriented automotive supply chain. Despite competition from countries with an early-developed automotive industry such as Thailand, Indonesia, and India, or the resource advantages of China, we believe that just as VinFast has become a major player in the global auto industry, smaller Vietnamese companies should also be confident in producing high-quality 'Made in Vietnam' components."

"Through this conference, CNC VINA, with its experience in machinery design, production lines, and a workforce of engineers and technicians with years of experience in international corporations, hopes to deepen its cooperation with VinFast in manufacturing other components, including stamping, welding, and painting processes."

"Finally, I would like to express my gratitude to VinFast for trusting CNC VINA and providing us with opportunities to collaborate and develop our internal capabilities over the years. We are proud to contribute to the development of Vietnam’s domestic automotive industry in the years ahead."

CNC VINA’s Commitment to VinFast’s Localization Goals

The "VinFast Automobile Localization" seminar on December 12 gathered valuable insights from experts, business leaders, and policymakers. It featured renowned figures in economics, technology, and the supporting industries, including macroeconomic experts such as Pham Chi Lan, Associate Professor Dr. Bui Quang Tuan, Dr. Nguyen Si Dung, Dr. Le Xuan Nghia, Professor Dr. Le Anh Tuan, Associate Professor Dr. Dinh Trong Thinh, Dr. Nguyen Minh Phong, and Dr. Nguyen Dinh Cung. Also present were leading experts in automotive technology, such as Associate Professor Dr. Dam Hoang Phuc, Associate Professor Dr. Ly Hung Anh, Dr. Nghiem Vu Khai, and Mr. Do Huu Hao.

VinFast introduced its latest advancements in electric bus production, sourcing manufacturing equipment from reputable suppliers in South Korea, Austria, and Sweden. Notably, the chassis engraving and camera inspection machines were supplied by CNC VINA, a Vietnamese company (as cited in CAFE F).

-large.webp)

Experts continue to praise VinFast for its impressive achievements in localization. Its strategy of developing electric vehicles and investing in domestic supply chains has been seen as a key factor in surpassing the 60% localization rate, overcoming challenges, and setting new industry benchmarks. Many have expressed admiration for VinFast’s advanced production processes, especially its ability to master critical components such as electric motors, batteries, and vehicle bodies.

Looking ahead, VinFast plans to implement a series of concrete measures, working closely with existing partners and leveraging an extensive network of auxiliary businesses to optimize local supply and reduce dependence on imports. CNC VINA remains committed to investing and meeting strict requirements to contribute to VinFast's localization targets.

Mass Production of Automotive Components at CNC VINA’s Factory

Tiếng

Anh

Tiếng

Anh

Tiếng Anh

Tiếng Anh