Titanium is another useful metal material for making jewelry, prosthetics, surgical instruments, aircraft, and many other things. Most of the time, it is laser engraved for identification and personalization. For example, prosthetics may be assigned an identification number or special rating using laser engraving.

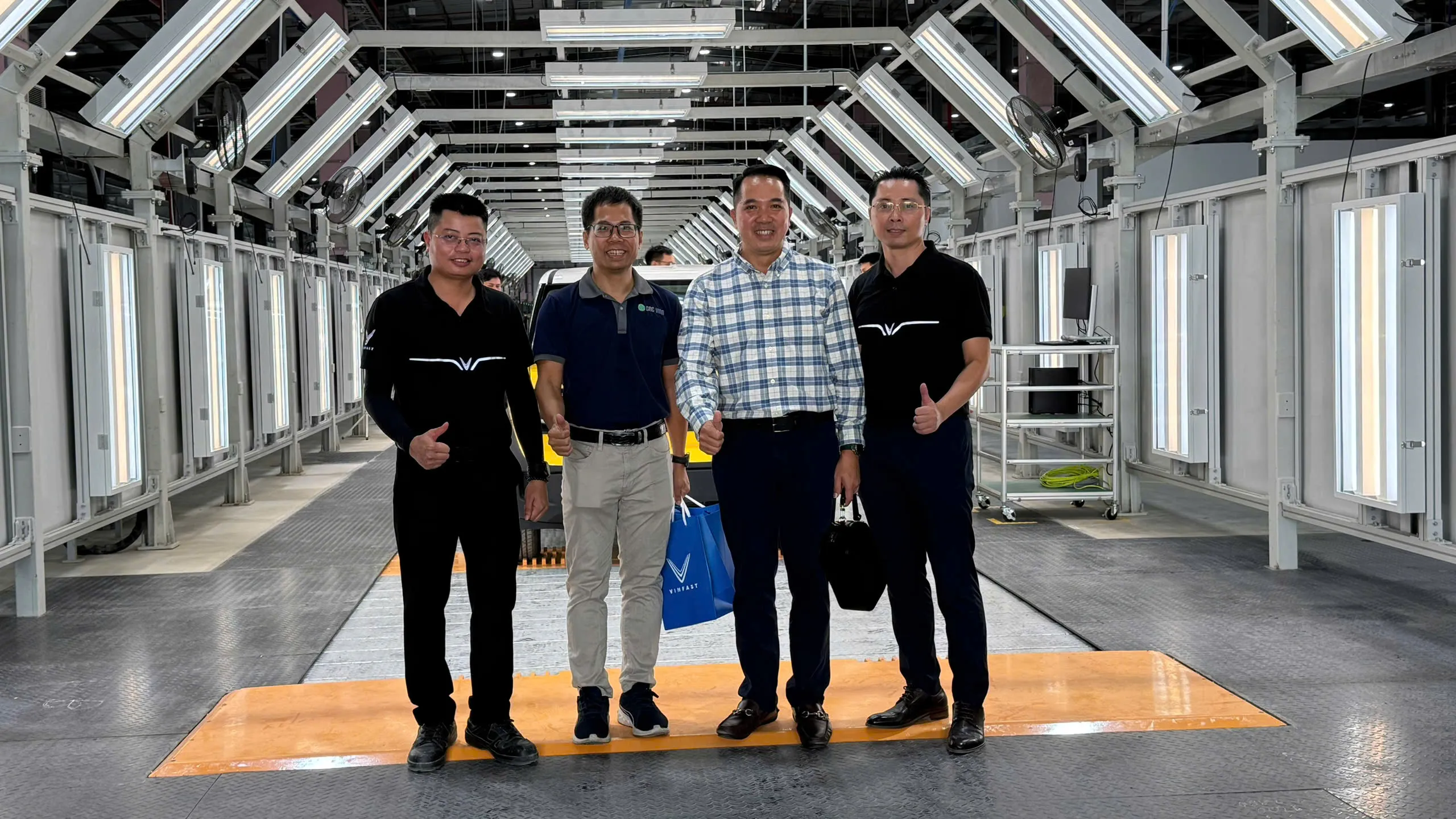

Metal laser engraving machine: Combining precision and efficiency in automotive industry

26/05/24

Definition

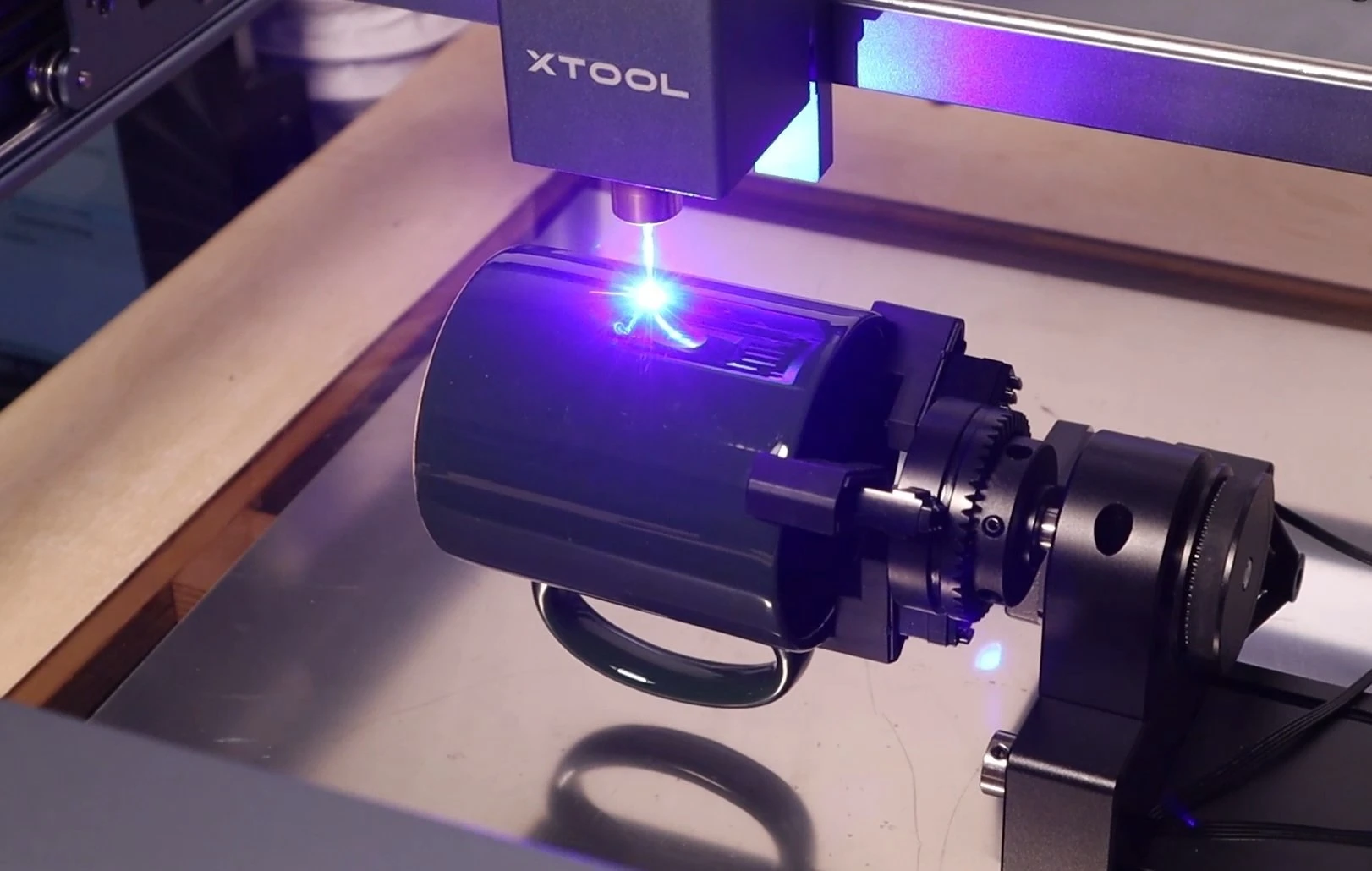

A metal laser engraving machine is a specialized machine that uses a laser beam to print and engrave on metal materials. Metal laser engraving produces products with clear, refined, and precise lines. Laser technology, with its advantages such as high speed, accuracy, and the ability to create various shapes, has made metal engraving and cutting easier and more efficient. This technology also minimizes labor and production time, meeting market demands and surpassing previous manual methods.

How does a metal laser engraving machine work?

The core of this process is the laser beam, an extremely powerful beam of light strong enough to erode the metal from the surface. When the laser beam hits the metal surface, it is absorbed by the metal. The metal uses that energy and evaporates, leaving an engraving mark on the metal. Chemically, this process is called sublimation, as the metal directly changes from a solid state to a gaseous state.

The intensity of the laser beam (power) can be adjusted and controlled by laser engraving software. It changes that intensity based on the design requirements. The laser beam attacks areas that need deeper engraving with a stronger intensity.

In some metals, we observe vibrant colors after engraving. Color laser engraving results from a reaction between the protective coating (oxide layer), such as on stainless steel, and the laser beam. The color varies depending on the type of metal, laser speed, and power. In uncoated or pure metals, these results might not be observable.

Metals that can be laser engraved

Stainless Steel

Stainless steel is one of the most popular choices today. It is used to make bottles, kitchen tools, utensils, surgical instruments, etc. All of these can be engraved or etched with a laser engraving machine. Stainless steel can be engraved with diode lasers, IR lasers, and CO2 lasers. To engrave stainless steel, you need a fiber laser engraving machine.

Steel

Steel is commonly used in our daily life. It is used to create tons of products and items. Steel can also be laser engraved or etched. Permanent markings are often made for identifying the manufacturer or parts.

Aluminum

Aluminum is another common metal used to make various items that we use in daily life, such as kitchen utensils, business cards, electronic products, etc. It can be engraved for personalization or identification.

Titanium

Benefits of using laser cutting machines in the automotive industry

Laser cutting produces clean, precise cuts

Laser cutting machines use a high-density heat source to cut, resulting in precise and clean cuts. The light waves produced by the laser cutting machine have a wavelength of 10,000 nm. Precise cutting is achieved by the metal absorbing some of this energy, which causes a change in the metal's molecular structure.

The Beam Parameter Product (BPP) is also used to evaluate the quality of the laser beam. For example, the BPP of a CO2 laser is typically 8–9 mm. This, along with a high concentration of heat, results in almost perfect cut quality, making this method widely used in the automotive industry.

Laser cutting machines are especially ideal for cutting and sealing airbags. They are considered virtually faultless when sealing airbag covers, which is why they are now the main technology used for cutting and sealing airbags in cars. The strong and precise heat of the laser cutting machine is the key advantage in sealing airbags.

Laser cutting machines are extremely versatile and can cut various materials

Laser cutting machines move precisely to cut programmed contours in the laser cutter since their cutting heads are CNC controlled. This technology is extremely useful in the automotive industry as it significantly reduces production time while consistently producing parts.

This also gives the technology the advantage of being very flexible in terms of versatility and design complexity. Materials like plastic, fabric, glass, and rubber are just a few used in the automotive industry, all of which can be successfully processed by a laser beam.

Components and materials that have undergone laser processing can be found in nearly every part of a standard car, including both exterior and interior components. Today, every step in the automotive production process, from initial design and development to final assembly, uses laser technology.

Laser cutting machines are compact compared to other tools

The compact nature of laser cutting machines is a key factor that has led to their widespread use in the automotive industry. Using a laser cutting machine becomes an efficient output factor beyond just space considerations for automotive manufacturers because it is relatively small compared to its throughput.

The compact nature of laser cutting machines allows them to be easily integrated into production lines. They take up minimal space, freeing up valuable floor space for other equipment.

The size advantage of laser cutting machines also means they can be used in smaller automotive shops without sacrificing the precision needed to produce high-quality parts.

Laser cutting machines process quickly and produce high-quality products

One of the advantages of laser cutting machines is their quick processing time. They are also known for producing high-quality cuts that achieve both precision and accuracy. These advantages make laser cutting machines ideal for streamlining the production process of automotive parts at all stages of car manufacturing: from design and part development to assembly.

Lasers frequently work alongside robotic systems due to the three-dimensional nature of some parts. In certain cases, robots pick up a part, bring it to a fixed processing head, and manipulate it as needed to complete the cutting process. Alternatively, the laser beam can be mounted on a robotic arm to guide the beam around the three-dimensional contours of the part.

The combination of these two techniques allows for a range of processes. It manages the workpiece and the laser head to carry out multiple cutting tasks as efficiently as possible. Typically, many laser processes can be performed in a single robot cell, speeding up production and reducing cycle times.

However, lasers are not only used in mass production. They are also being used in custom, high-end automotive manufacturing, where low productivity and some manual work still take place.

Here, the goal is to enhance processing quality, repeatability, and reliability rather than increasing scale or accelerating production speed. This reduces rejection rates and minimizes waste of expensive materials. This capability makes laser cutting machines ideal for both small-scale and large-scale production.

Laser cutting can engrave materials in one step

Laser marking/engraving is more cost-effective compared to other alternative solutions as it does not have the high consumable costs associated with inkjet technology. In most cases, laser cutting produces a more durable and permanent mark that cannot be erased. Hot stamping provides durability and high-quality branding, but it sacrifices flexibility as each label requires a different mold.

In contrast, laser marking is fast, flexible, and easily adaptable. The information and images being marked can be quickly modified without the need to change tools or stop production.

Tiếng

Anh

Tiếng

Anh

Tiếng Anh

Tiếng Anh