How has the brake oil pump revolutionized the automotive industry?

Introduction

Definition of a brake fluid pump

A brake fluid pump is a device used to fill hydraulic brake fluid into the brake systems of vehicles such as cars and motorcycles.

These machines are designed to facilitate the maintenance and servicing of hydraulic brake systems by accurately filling them with brake fluid to maintain pressure and operational efficiency, ensuring smooth and safe braking system performance.

The importance of brake fluid in the automotive industry

Brake fluid transmits force from the brake pedal to the brake calipers or wheel cylinders. This force transmission is essential to convert the driver’s mechanical input into hydraulic pressure to activate the brakes.

If the brake fluid level is low, contaminated with moisture, or diluted with water, it can impair braking capability. In such cases, replenishing or replacing the brake fluid is crucial to avoid the following consequences:

-

Reduced braking performance: Inadequate lubrication and poor force transmission can make the brakes less effective, posing safety risks during vehicle operation and potentially endangering lives.

-

Damage to brake components: Brake fluid is hygroscopic, meaning it absorbs moisture. Water in the fluid can cause rust in brake parts. Over time, degraded fluid lowers its boiling point, leading to corrosion of components.

Thus, it is vital to ensure both the quality and the correct volume of brake fluid during the filling process.

Overview of traditional brake fluid filling methods

Manual procedure

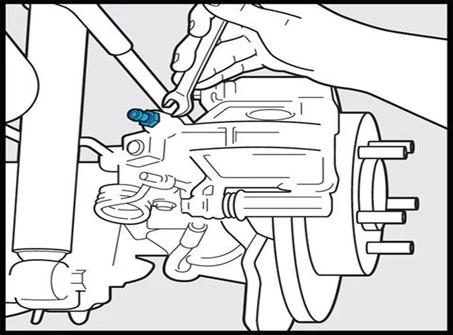

Manual brake fluid filling requires careful attention to detail and adherence to safety procedures to effectively service a vehicle’s braking system. The steps include:

- Preparation: Gather the necessary tools and equipment, including suitable brake fluid, a funnel, gloves, safety goggles, and rags for cleanup.

-

Locate the brake fluid reservoir: Usually mounted on or near the master cylinder under the hood. These reservoirs are often translucent to allow for visual fluid level checks.

-

Check the fluid level: Low fluid levels may indicate regular wear or potential leaks.

-

Open the reservoir: Open the cap carefully to avoid contamination. Some reservoirs have screw caps, while others use snap or twist locks.

-

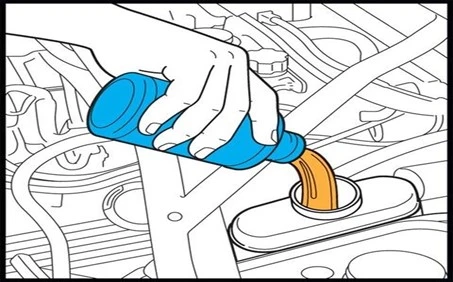

Add brake fluid: Use a funnel to pour the specified type of brake fluid into the reservoir to prevent spillage. It’s essential to use the correct fluid as recommended by the vehicle manufacturer.

-

Monitor fluid levels: Periodically check the fluid level to prevent overfilling, which may cause overflow and damage nearby components.

-

Close the reservoir and clean up: Immediately clean any spilled fluid to avoid surface damage or corrosion.

-

Check brake pedal feel: After refilling, check the brake pedal for proper resistance to ensure the system is functioning correctly.

Time and labor intensive

Traditional methods are time-consuming, especially when servicing multiple vehicles or during routine maintenance at repair shops. Each vehicle requires individual attention, leading to increased service times.

Labor - intensive: Manual filling relies on human effort. Technicians must physically fill the reservoir, which can be tiring—especially when dealing with many vehicles or complex systems.

Higher risk of human error

Manual methods are prone to errors such as incorrect fluid levels, contamination, or spillage. Air bubbles may also enter the system during manual filling, resulting in spongy brakes or reduced braking efficiency.

Features and benefits of liquid brake fluid pumps

Automated process

Brake fluid pumps automate the process of filling brake fluid into the braking system. They are equipped with mechanisms to accurately measure and dispense the required amount of brake fluid, reducing the need for manual intervention.

Fast and efficient

The automated pumping processes provided by these machines are significantly faster and more efficient than manual methods. They can drastically reduce the time needed to complete brake fluid filling tasks, there by improving productivity and workflow in automotive repair shops and service centers.

Labor cost reduction and time savings

With automated pumping processes, time and effort that would otherwise be spent on manual filling tasks are saved. This allows technicians to focus on other operations, enhancing overall operational efficiency, saving time, and reducing labor costs.

Accurate fluid level control

Brake fluid pumps provide precise control over the amount of fluid dispensed, ensuring accurate filling and optimal brake system performance.

Ensure proper brake performance

By maintaining the correct fluid level in the braking system, these machines help ensure consistent and reliable braking performance, enhancing vehicle safety and driver confidence.

Minimize overfilling or underfilling risks

Automated filling minimizes the risk of overfilling or underfilling the brake system, preventing potential issues such as fluid leaks, brake fade, or reduced braking efficiency.

Flexibility and adaptability

Brake fluid pumps are highly flexible and adaptable, suitable for use with various types of brake fluid and compatible with a wide range of vehicle models and sizes. This flexibility makes them valuable assets in diverse automotive maintenance and repair environments.

Compatible with various brake fluid types

These machines are designed to operate with multiple types of brake fluid. This compatibility ensures flexibility and convenience for technicians working on different kinds of vehicles.

Suitable for multiple vehicle models and sizes

Whether servicing cars, trucks, motorcycles, or other vehicles, liquid brake fluid pumps can accommodate a wide range of vehicle types and sizes, making them a versatile solution for automotive repair shops and service centers.

Impact of liquid brake fluid pumps on the automotive industry

Brake fluid pumps have had a positive impact on the automotive industry by improving production efficiency, product quality, and safety, while also reducing costs and waste. Their adoption is becoming increasingly widespread as manufacturers seek to optimize operations and meet the demands of a competitive market.

Increased production efficiency

Liquid brake fluid pumps streamline the brake fluid filling process, resulting in higher production efficiency at automotive manufacturing facilities. Faster and more accurate dispensing contributes to increased production speed and output.

Faster brake fluid filling

The automated filling process provided by these machines allows for quicker brake fluid replenishment in vehicles, reducing assembly line downtime and boosting productivity.

Streamlined assembly line operations

By automating a critical aspect of vehicle assembly, liquid brake fluid pumps help simplify operations on the assembly line. They reduce bottlenecks and ensure a smoother workflow throughout the production process.

Enhanced product quality

Stable and accurate fluid levels achieved through liquid brake pumps contribute to improved product quality. Properly filled brake systems result in better vehicle performance with enhanced safety and reliability.

Consistent and precise fluid levels

Brake fluid pumps ensure consistent and precise fluid levels across all vehicles, eliminating the variability that can occur with manual filling methods. This consistency enhances product quality and customer satisfaction.

Improved brake performance and safety

Properly filled braking systems, enabled by liquid brake fluid pumps, enhance brake performance and safety. Ensuring the correct fluid level contributes to optimal braking functionality and reduces the risk of brake-related accidents or malfunctions.

Cost savings and profitability

The efficiency gained and reduced labor costs associated with liquid brake fluid pumps lead to overall cost savings for automotive manufacturers. Increased productivity and lower operating expenses ultimately improve profitability.

Reduced labor costs

Automated filling processes minimize the need for manual labor in brake fluid filling tasks, lowering labor expenses for automotive manufacturers. This allows for more effective allocation of resources to other areas of production or maintenance.

Minimized material waste

By precisely controlling the amount of brake fluid dispensed, liquid brake fluid pumps help minimize material waste. This contributes to sustainability efforts in the automotive industry and reduces costs related to excess fluid usage.

Conclusion

Liquid brake fluid pumps have delivered significant benefits and impact to the automotive industry, revolutionizing the brake fluid filling process while enhancing efficiency, safety, and product quality.

-

Increased production efficiency: These machines streamline the brake fluid filling process, leading to faster production speeds and reduced assembly line downtime.

-

Enhanced product quality: By ensuring stable and accurate fluid levels, they contribute to improved brake performance and vehicle safety.

-

Cost savings: Reduced labor costs and minimized material waste result in overall cost savings for automotive manufacturers.

-

Improved safety: Properly filled brake systems enhance vehicle safety by reducing the risk of brake-related accidents or failures.

Future outlook and potential advancements

The future outlook points to continued advancements aimed at further improving efficiency, safety, and sustainability in vehicle manufacturing and maintenance processes.

-

Integration with smart systems: Integration with smart systems and Industry 4.0 technologies could enable remote monitoring, predictive maintenance, and data-driven insights for further optimization.

-

Advanced automation: Advances in automation technology may lead to even faster and more efficient pumping processes with minimal human intervention.

-

Enhanced fluid level control: Future machines may offer even more precise fluid level control, ensuring optimal performance and reliability.

If you are interested in brake fluid pumps, please contact CNC VINA today to receive prompt consultation and the earliest quotation for the product!

Tiếng

Anh

Tiếng

Anh

Tiếng Anh

Tiếng Anh