In practice, a modern automotive assembly line requires various types of machinery, equipment, and accessories such as automatic paint sprayers, plastic molding machines, industrial robotic arms, CNC welding machines, and measuring devices.

What is an automotive assembly line?

16/05/24

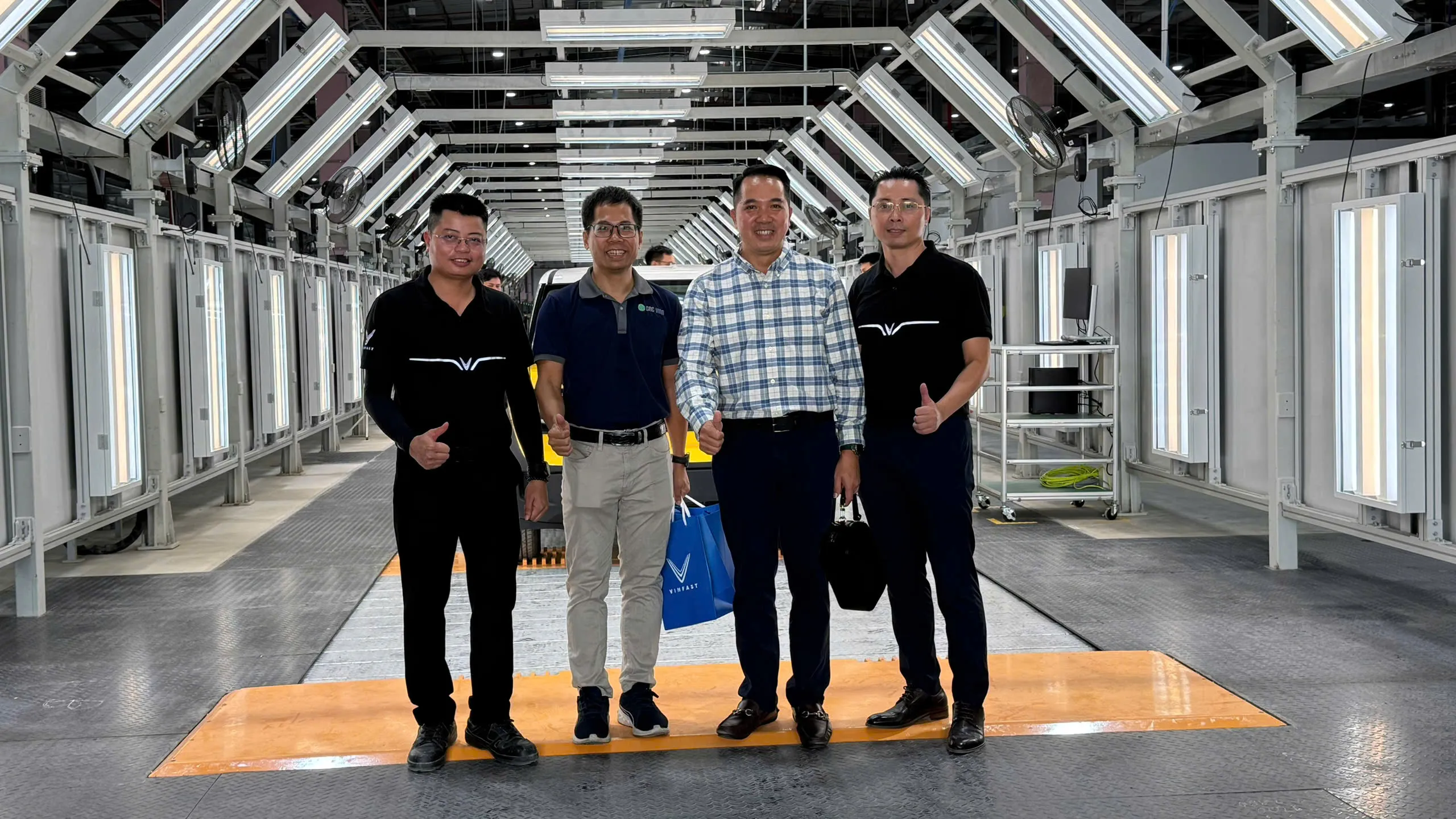

Introduction

Overview of the automotive assembly line

The automotive assembly line is a production system in the automotive industry, where vehicles are assembled sequentially from individual components and parts. This process typically occurs in automobile manufacturing plants and is designed to optimize performance, minimize production time, and ensure the quality of the final product.

The process is complex and includes multiple stages, from vehicle design and its components to the assembly of parts, vehicle testing, and ultimately delivering the vehicle to the customer.

Automobile assembly requires specialized equipment, highly trained technicians, and various raw materials.

The Importance of the assembly line in automobile production

Vehicle manufacturing is a multi-step process, moving from individual parts to the complete assembly and finishing of the vehicle. Nowadays, all automakers aim to automate their production processes to achieve the highest performance and quality, which results in profits for the company.

The assembly line is a crucial and indispensable part of automobile production, playing a decisive role in increasing productivity, ensuring quality, saving costs, enhancing flexibility, and creating consistency in the product.

Explaining what an automotive assembly line is and how it works

An automotive assembly line is a production system designed to automate the process of assembling automobile components and parts from individual pieces to a complete product.

It is an integral part of modern automobile manufacturing and is primarily responsible for transforming parts and components into a final product that can be sold on the market. The basic operation of an automotive assembly line involves:

Preparation and reception of components:

The assembly line begins by receiving components and parts from various suppliers.

These parts are grouped together and prepared for the next step in the assembly process.

Assembly of parts and components

The components are introduced to the line, and workers or robots assemble them following specific steps.

The assembled parts may include the engine, transmission, chassis, wheels, and other systems such as suspension, air conditioning, and electrical systems.

Testing and quality control

Each step in the assembly process is thoroughly checked to ensure that every part is correctly assembled and meets quality standards.

Inspection steps may include visual checks, functional testing, and overall quality checks.

Painting and finishing

Once the parts are assembled, the vehicles typically go through painting and finishing stages.

This process includes painting, sanding, and finishing the surfaces to create the final appearance and protect against weather and environmental effects.

Final testing and packaging

After completing the assembly and finishing process, each vehicle undergoes a final inspection to ensure it meets all quality and safety standards.

Then, the vehicles are packaged and prepared for shipment to dealers or end customers.

Definition and key characteristics of the automotive assembly line

Definition of the automotive assembly line

An automotive production line is a system of equipment and machinery, both automatic and semi-automatic, installed and used in the automotive manufacturing industry. Its function is to carry out production operations in a sequential, continuous manner according to a pre-established program.

Main components and equipment used in the assembly line

In an automotive assembly line, various types of components and equipment are used to perform the assembly and quality control steps. Some of the main components and equipment typically used in an automotive assembly line include:

- Industrial robots: Robots are used to perform specific assembly tasks, such as installing components like engines, gearboxes, or interior parts. These industrial robots are programmed to perform repetitive tasks with high precision and efficiency.

- Conveyor systems and transfer machines: Conveyor systems and transfer machines are used to move components and vehicles through workstations on the assembly line. This ensures a continuous production process and optimizes the flow of products.

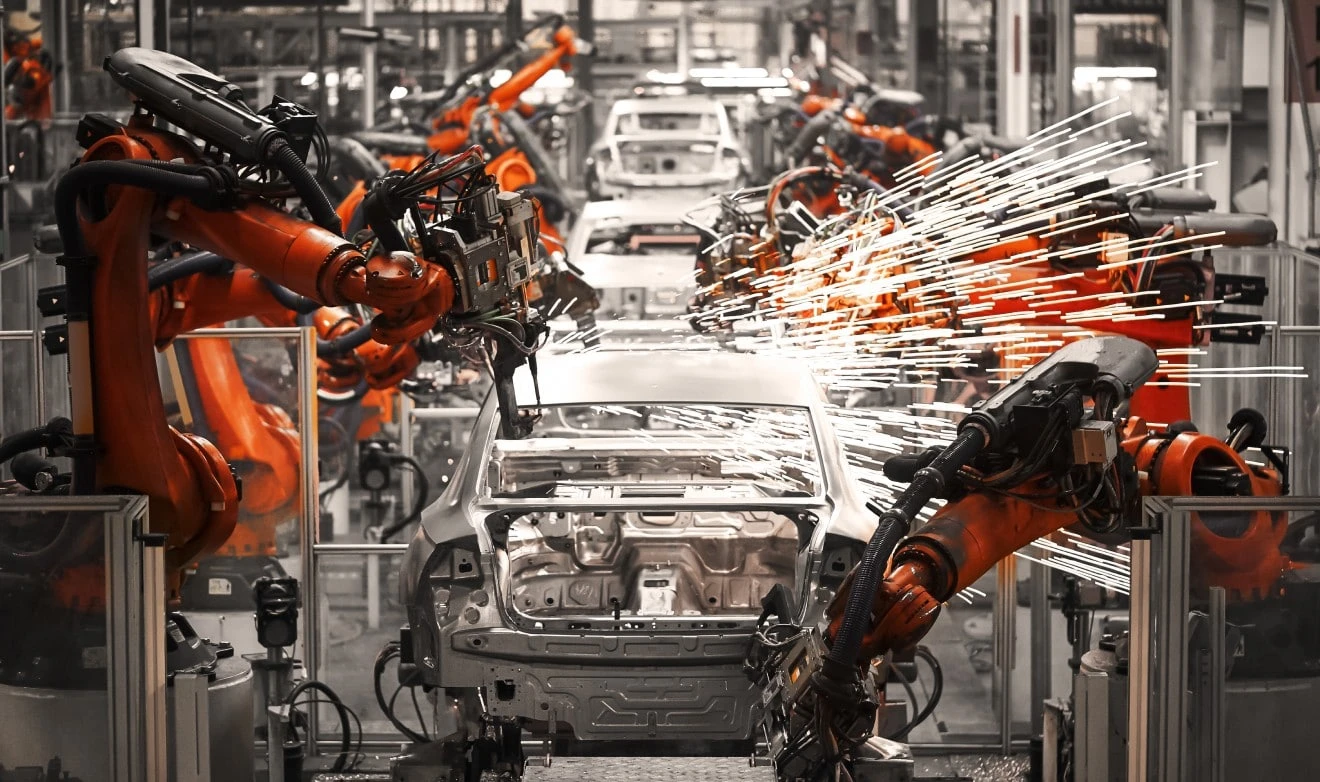

- Welding machines: Welding machines are used to join metal parts of the vehicle, such as the chassis and other components, through the welding process. Types of welding machines may include spot welders, high-intensity welders, and laser welders.

- Cutting and machining machines: Cutting and machining machines are used to fabricate and process metal and plastic parts in the automotive assembly process. These machines include laser cutters, plasma cutters, CNC machining centers, and milling machines.

- Quality control systems: Quality control systems are used to ensure that each vehicle meets quality and safety standards. These systems may include vision inspection systems, dimensional measurement machines, force and pressure testers, and functional testers.

- Automated control systems: Automated control systems are used to control and monitor the operation of the automotive assembly line. This includes programming robots and machinery, monitoring product flow, and adjusting the production process to achieve optimal performance.

Work process in the automotive assembly line

The work process in an automotive assembly line is typically organized systematically and efficiently to ensure that each step in the production process is performed accurately and with high performance. Below is an overview of the work process in an automotive assembly line:

Plan:

-

Determine production requirements: The production management team determines production needs based on market data and customer orders.

-

Production planning: Based on production needs, a plan for the assembly line is developed, including a production schedule, labor allocation, and resource management.

Procure:

-

Order components and materials: Necessary parts and materials for the assembly process are ordered from reliable suppliers.

-

Inspection and receipt of goods: Upon arrival, parts and materials are quality checked before being sent to the assembly line.

Production:

-

Assembly and montage: Parts and components are assembled into sub-assemblies. These sub-assemblies are then assembled into a complete vehicle.

-

In-Process quality control: During production, quality control steps are taken to ensure that each assembly step meets quality standards.

Quality control:

-

Final inspection: Once the vehicle is complete, a final inspection is conducted to ensure that all components work correctly and meet safety and quality standards.

-

Adjustment and repair: If any defects are detected during quality checks, the vehicle is adjusted and repaired to meet the required standards.

Packaging and shipping:

-

Product packaging: The vehicle is safely packaged to prevent damage during shipping.

-

Shipping to destination: The vehicle is transported to its final destination, including car dealerships or end customers.

Role of automation and robots in modern assembly lines

Thanks to automated assembly lines, factories have significantly increased production efficiency, reducing cycle time for each production stage and ensuring the highest accuracy levels.

-

Improved product quality: Automation helps set precise specifications for products before production, especially in mechanical processing, where automation ensures accurate dimensions and almost perfect tolerances.

-

Reduced labor costs: Automation replaces human labor in many tasks, particularly those that exceed human speed and endurance.

-

Risk reduction: Automation minimizes production interruptions caused by human-related factors such as tardiness or illness, helping businesses save on recruitment and training costs.

-

Optimized operational time: Automated machinery and robots can operate 24/7 with minimal downtime.

Functions and relevant departments in the automotive assembly line

Overview of different departments and their roles

In an automotive assembly line, several departments and units play crucial roles in the production process. Below is an overview of the various departments and their roles:

Metalworking shop:

-

Role: The metalworking shop is typically responsible for manufacturing and processing metal parts required for vehicles, including the chassis, doors, thresholds, and other components.

-

Activities: The shop usually has metalworking equipment such as cutting machines, milling machines, welding machines, and lathes to produce metal parts according to specific designs.

Paint shop:

-

Role: The paint shop is where the protective and aesthetic layers are applied to the vehicle’s surface, including the primary paint layer and protective coatings.

-

Activities: Tasks in the paint shop include surface preparation, applying base coats, applying protective coatings, and using techniques such as spraying or water-based painting to create the final vehicle surface.

Assembly shop:

-

Role: The assembly shop is where parts and components are assembled into sub-units and then assembled into a complete vehicle.

-

Activities: Tasks in the assembly shop include installing components such as the engine, gearbox, suspension, electrical system, interior systems, and other parts to create a complete vehicle.

Quality control shop:

-

Role: The quality control shop is where quality checks are performed to ensure each vehicle meets quality and safety standards.

-

Activities: Tasks in this shop include inspecting parts and finished products, detecting and repairing defects, and ensuring all products comply with regulations and standards.

Collaboration and integration between different departments

Collaboration and integration between different departments in the automotive assembly line are crucial to ensure that the production process runs efficiently and without interruption. Here are some ways in which different departments in the automotive assembly line collaborate and integrate:

Collaboration in the assembly process:

Workers and robots in the assembly shop need to cooperate closely to perform specific assembly tasks according to the production plan.

Departments such as the painting shop and the assembly shop need to coordinate to ensure that the cars are painted and assembled in the correct and efficient order.

Integration of quality control

The quality inspection and control department must be integrated into the production process to ensure that every product meets the required quality and safety standards.

Different departments need to collaborate with the quality inspection department to provide the necessary information and data for performing quality checks.

The importance of quality inspection and control in the assembly line process

Quality inspection and control in the automotive assembly line process are extremely important and indispensable factors.

- Ensuring safety: Quality control ensures that each car produced meets the highest safety standards. Errors or defects in the assembly process can lead to serious safety issues for drivers and passengers.

- Protecting brand reputation: Poor-quality vehicles can seriously damage the manufacturer's brand reputation. A car that fails to meet quality standards can lead to lawsuits, high recalls, and loss of customer trust.

- Saving future repair costs: Detecting and fixing errors early in the production process helps save on future repair costs. Repairing defects after the car has been shipped can be much more expensive than identifying and addressing them from the beginning.

- Improving product quality: Continuous quality inspection throughout the production process helps identify opportunities to improve and enhance product quality. This may include adjusting the production process, upgrading technology, or providing staff training.

Benefits and challenges of the automotive assembly line

Benefits of the automotive assembly line

Production efficiency:

Increased productivity: The automotive assembly line enables continuous production, which helps increase productivity compared to traditional manual manufacturing methods.

Process optimization: The automotive assembly line is designed to optimize the production process, from component preparation to assembly and quality control, helping to reduce time and enhance performance.

Cost efficiency

-

Reduced labor costs: Using an automotive assembly line instead of manual labor helps reduce labor costs and increases efficiency.

-

Resource optimization: The assembly line allows for the optimization of resources such as materials, energy, and time, helping to reduce overall production costs.

Standardization

-

Ensured consistent quality: Automotive assembly lines are often designed with standardized processes and procedures, helping to ensure consistent product quality and compliance with industry standards.

-

Easier management and control: The assembly line allows for easier and more effective management and control of the production process, from tracking production progress to monitoring quality.

Challenges faced in implementing and maintaining the assembly line

Intense competition

The automotive industry faces fierce competition from both domestic and international manufacturers. This creates significant pressure on automakers to improve performance, reduce costs, and enhance quality to remain competitive in the market.

Changing market demands

The demand in the automotive market can change rapidly due to customer requirements, economic fluctuations, and regulatory changes. This presents a challenge for automakers to adapt quickly to these changes and meet new requirements.

Workforce management

Ensuring that there is enough skilled and trained labor to operate and maintain the automotive assembly line is a challenge for manufacturers. They must ensure that workers are properly trained and capable of working in a complex production environment.

Risk management

The operation of an automotive assembly line can encounter risks such as technical failures, safety hazards, and product loss. This requires automakers to have effective risk prevention and mitigation plans to ensure safety and stability in the production process.

How to address challenges and improve assembly line performance

Investing in technology and automation

Implement advanced technology and automation in the assembly line to enhance efficiency and minimize human error.

Use robots and automated systems to handle repetitive and hazardous tasks, helping to improve productivity and ensure quality.

Optimizing the production process:

Apply quality management methods such as Lean Manufacturing and Six Sigma to eliminate waste and optimize the production process.

Implement data analysis and digitize the production process to identify improvement opportunities and optimize performance.

Training and employee development

Invest in training and development to enhance employees' skills and knowledge of production processes and new technologies.

Create an environment that encourages creativity and employee contributions to improve workflows and increase engagement.

Enhancing risk management

-

Develop risk prevention and response plans to minimize the negative impact on the assembly line operations.

-

Use technologies such as monitoring and alert systems to detect problems and risks early in the production process.

Trends and innovations in the future of the automotive assembly line

Overview of emerging technologies and concepts

In the future, automotive assembly lines are expected to continue evolving and transforming to meet increasing demands for performance, flexibility, and quality. Some trends and innovations expected in the future of the automotive assembly line include:

Industry 4.0:

Industry 4.0 is the trend of integrating digital technologies into the production process, creating a smart and highly automated manufacturing environment. In the automotive assembly line, Industry 4.0 will bring synchronized connectivity between devices, machinery, and systems, improving management and control of production.

Internet of things (IoT):

IoT will play a critical role in creating a smart network within the automotive assembly line. IoT sensors integrated into devices and machinery will collect real-time data on performance, status, and operating conditions, helping to optimize the production process and predict potential issues.

Advanced automation:

Automation will continue to advance and become more sophisticated in the automotive assembly line. Robots and automated systems will perform more tasks, from simple assembly jobs to more complex tasks such as quality control and maintenance.

Artificial intelligence (AI) and machine learning:

AI and Machine Learning will be widely applied in automotive assembly lines to enhance predictive capabilities and analysis. These technologies will help optimize the production process, detect potential issues early, and improve quality management.

The impact of electric and autonomous vehicles on the automotive assembly line process

Electric and autonomous vehicles are driving innovation and profound changes in the automotive manufacturing process, requiring flexibility and adaptability within the automotive industry to meet the demands of the market and new technologies:

Component design and production:

Electric vehicles typically have different structures and engine systems compared to internal combustion engine vehicles, which requires changes in the component production process. Parts such as lithium-ion batteries, electronic control systems, and electric motors need to be manufactured and assembled according to new processes.

Autonomous vehicles require complex sensors, cameras, and control systems to ensure safe self-driving capability. This also necessitates changes in the production and assembly processes for electronic components and sensors.

Integration of digital technologies:

Electric and autonomous vehicles often integrate various digital technologies such as artificial intelligence, machine learning, IoT, and automated control systems. The production process must be adjusted to incorporate these technologies into the assembly line and quality control processes.

Using data from sensors and monitoring systems in autonomous vehicles helps improve the production process and quality control. This technology enables real-time monitoring and automatic adjustments to the production process based on live data.

Employee training:

Autonomous vehicles require employees to have advanced skills and knowledge, particularly in automated control systems and artificial intelligence. Therefore, there is a need to develop new training programs to equip employees for work in this new manufacturing environment.

Potential improvements and advancements in assembly line operations

Several potential improvements and advancements could occur in the automotive assembly line operations, including:

Enhanced automation:

Using more advanced robots and automation systems to perform assembly and quality control tasks. Integrating artificial intelligence and machine learning will improve automation capabilities and enhance flexibility within the production process.

Utilizing digital technologies:

Leveraging digital technologies such as IoT, artificial intelligence, and blockchain to optimize production processes, monitor machine performance, and predict potential issues early. Data analytics will be applied to optimize the assembly line and improve product quality.

Making the assembly line more flexible:

Designing automotive assembly lines to be flexible and adaptable to varied and changing production requirements. Using modular technology and modular design will reduce the time needed to switch between different models and types of vehicles.

Process optimization:

Conclusion

The automotive assembly line is a continuous system of production processes, from assembling components and parts to the final completion of the automobile product. Originating from the Industrial Revolution and the innovations of Henry Ford, the assembly line has evolved to become the centerpiece of modern automotive manufacturing. The assembly line plays a decisive role in the performance, quality, and cost of automobile production, while also having a significant impact on competition and the development of the automotive industry. Trends and innovations for the future include the integration of Industry 4.0 technologies, IoT, advanced automation, and the development of electric and autonomous vehicles.

The automotive assembly line is not only the heart of the automotive manufacturing process but also a key factor in determining the performance, quality, and competitiveness of automotive companies in the market.

The automotive assembly line plays an extremely important role in the automotive industry, where the most advanced technologies are applied to produce high-quality and high-performance products. To keep up with the rapid development of technology in this field, staying updated with the latest advancements is essential.

Tiếng

Anh

Tiếng

Anh

Tiếng Anh

Tiếng Anh